DXtra Intelligent Slickline Conveyance System

Enabling faster decision making at the wellsite

The DXtra™ intelligent slickline conveyance system offers the benefits of both e-line telemetry and mechanical slickline—giving you the insight, control, versatility, and efficiency of both worlds.

Within a high strength capillary tube based slickline, the electrical conductor provides bi-directional telemetry and power delivery to all standard cased hole logging sensors, meaning that you can utilise your existing cased hole equipment and make your CAPEX go further. High resolution data is transmitted in real time to the surface, enabling faster decision making and increased productivity at the wellsite.

Seamlessly integrating with your existing NOV wireline surface equipment, the DXtra system allows you to maximize your asset utilization and minimize additional capital investments.

DXtra provides leading-edge performance, reliability, and safety all in one robust package—reducing cost, QHSE risk, equipment handling, and manpower requirements at the wellsite.

Features and benefits:

- Universally adaptable to industry standard cased hole surface equipment, systems, and downhole tools

- Eliminates risks associated with the use of lithium batteries

- Reduced crew and equipment at the wellsite

- High resolution, real-time data acquisition for faster decision making

- Precise depth control and correlation throughout the operation

- Corrosion resistant 0.189-in. (4.8 mm) OD cable

- 3100 lb. maximum breaking strength

- Maximum temperature rating of 390 °F (200 °C)

- Cable lengths available from 25,000ft - 40,000ft +

- Improves quality and reliability of downhole data quality

Related Products

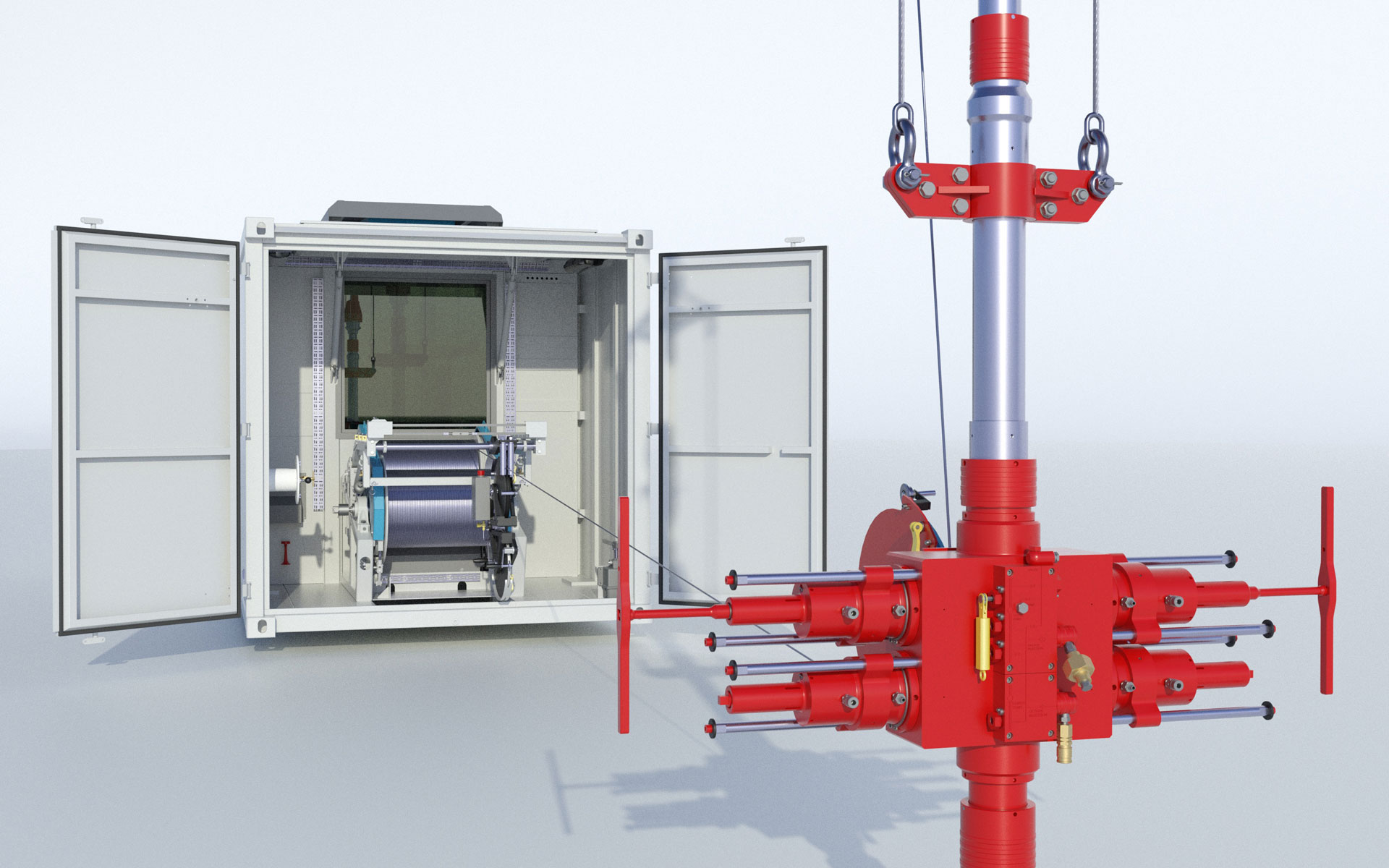

Slickline Pressure Control Equipment String

Reduce your operating costs with simple to operate, durable, and easy to maintain WPCE.

SlimLine Wireline Winch

Compact, self-contained wireline winch system for slickline and braided line operations

QuickLoad Slickline Stuffing Box

Mitigate the risk of hydrocarbon release during slickline well interventions with evolutionary wireline pressure control equipment.

Wireline Frac Solutions

From field-proven Artex trucks to lightweight well pressure control equipment, we offer all the wireline equipment to make you successful on the frac site.

Intervention and Stimulation Aftermarket Solutions

Reduce total cost of ownership of your coiled tubing, stimulation, acidizing, wireline, sand handling, and cementing equipment with our aftermarket solutions.

Related Tools