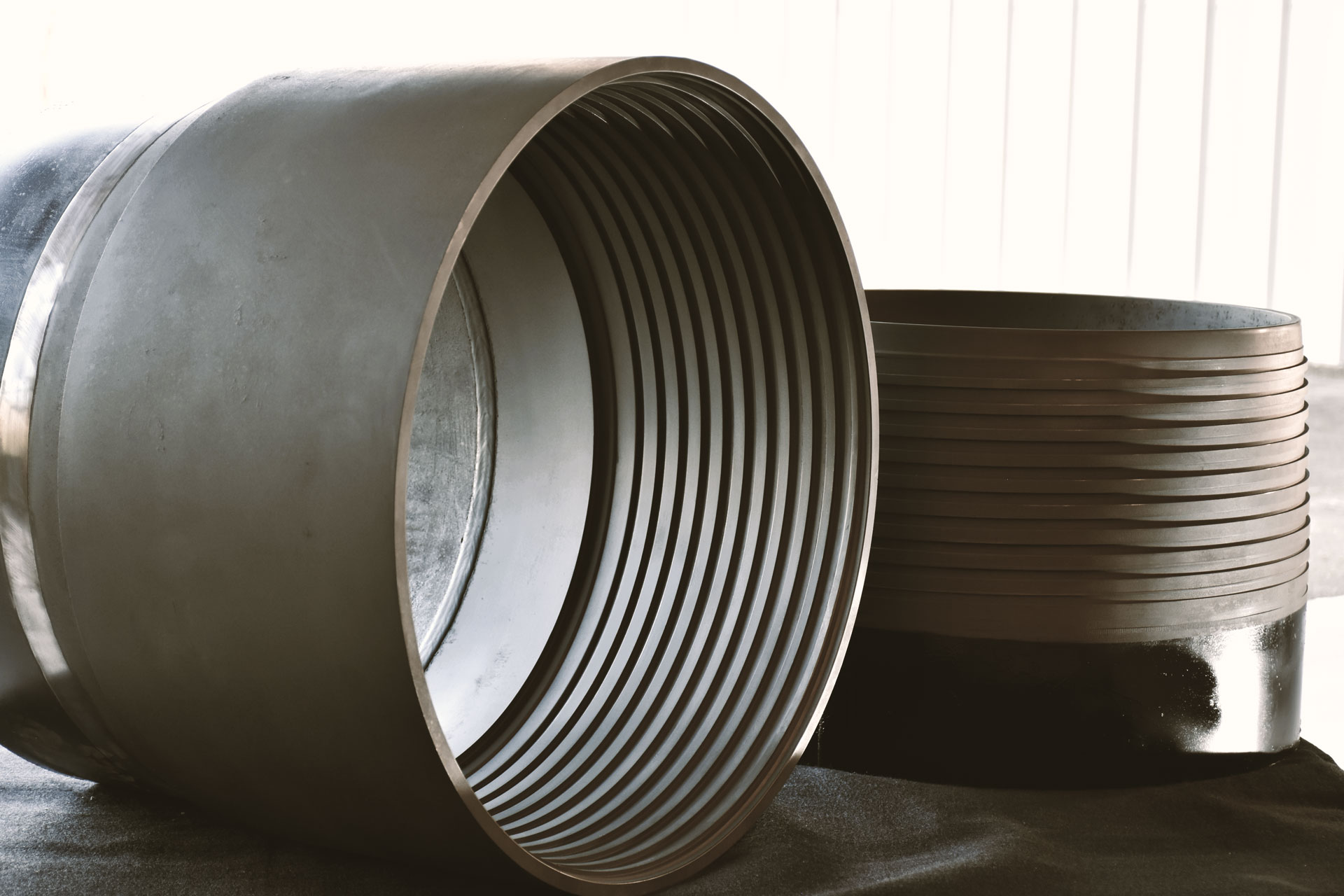

XLW-S Connectors

Improved evolution of our robust and reliable XLW wedge thread connector.

Built upon XLW’s unique hybrid design and 35-year run history, XLW-S connectors are an improved evolution of our XLW wedge thread connector. XLW-S connectors maintain the same characteristics as the XLW connector and use innovative features from the XLW-GT, generating a superior design with the same reliable performance. Similarities include full pipe body structural strength, metal-to-metal primary pressure seal, and wedge thread design, creating the largest possible contact surface area at makeup, providing superior compression and several times the torque strength of most competing technologies.

Added features include a slimmer profile that provides a more cost-effective option for onshore and offshore conductor and surface casing applications. With its full pipe body strength and pressure ratings, XLW-S provides excellent fatigue resistance and is supported by finite element analysis (FEA) and full API 5C5 CAL I (liquid and gas) sealability testing. This rigorous testing demonstrates that the connectors match full pipe body pressure envelopes even in worst-case geometric tolerance conditions.

We designed and developed XLW-S connectors using the latest digital design and simulation tools to create a new evolution in wedge thread performance.

XLW-S connectors are manufactured in 20- to 48-in. diameters with up to 1.00-in. wall thickness and can makeup with either power or manual tongs.

Applications

- Casing strings and liner strings with liquid pressure sealing requirements

- Heavily loaded surface casing strings

- Deepwater casing strings run in open water

- Conductors for subsea wells

- Casing for deviated wells

- Drilling with casing

- Alternative energy

Features

- Slimmer profile

- Breakout torque resistance eliminates the need for anti-rotation locking devices

- Connector ratings equal full pipe body strength

- Hybrid design

- Integral lift shoulder with a slimmer design

- Internal metal seal

- Wedge thread technology

Benefits

- Reliable performance under extreme loading conditions

- Easy running and handling offshore

- Reliable pressure integrity

- Easy spin-up, high torque capacity, and excellent resistance to anti-rotation

- Full API 5C5 CAL I (liquid and gas) sealability testing

Related Products

XLW Connectors

Combining the integrity of a wedge thread connector with the strength of a weld-on connector.

XLW-GT Connectors

Gas-tight internal metal seal designed for high performance under gas pressure loading.

Explore More

XL Systems Specs Direct

Specs Direct provides standard connector performance data sheets for the most common pipe and connector configurations offered by XL Systems.