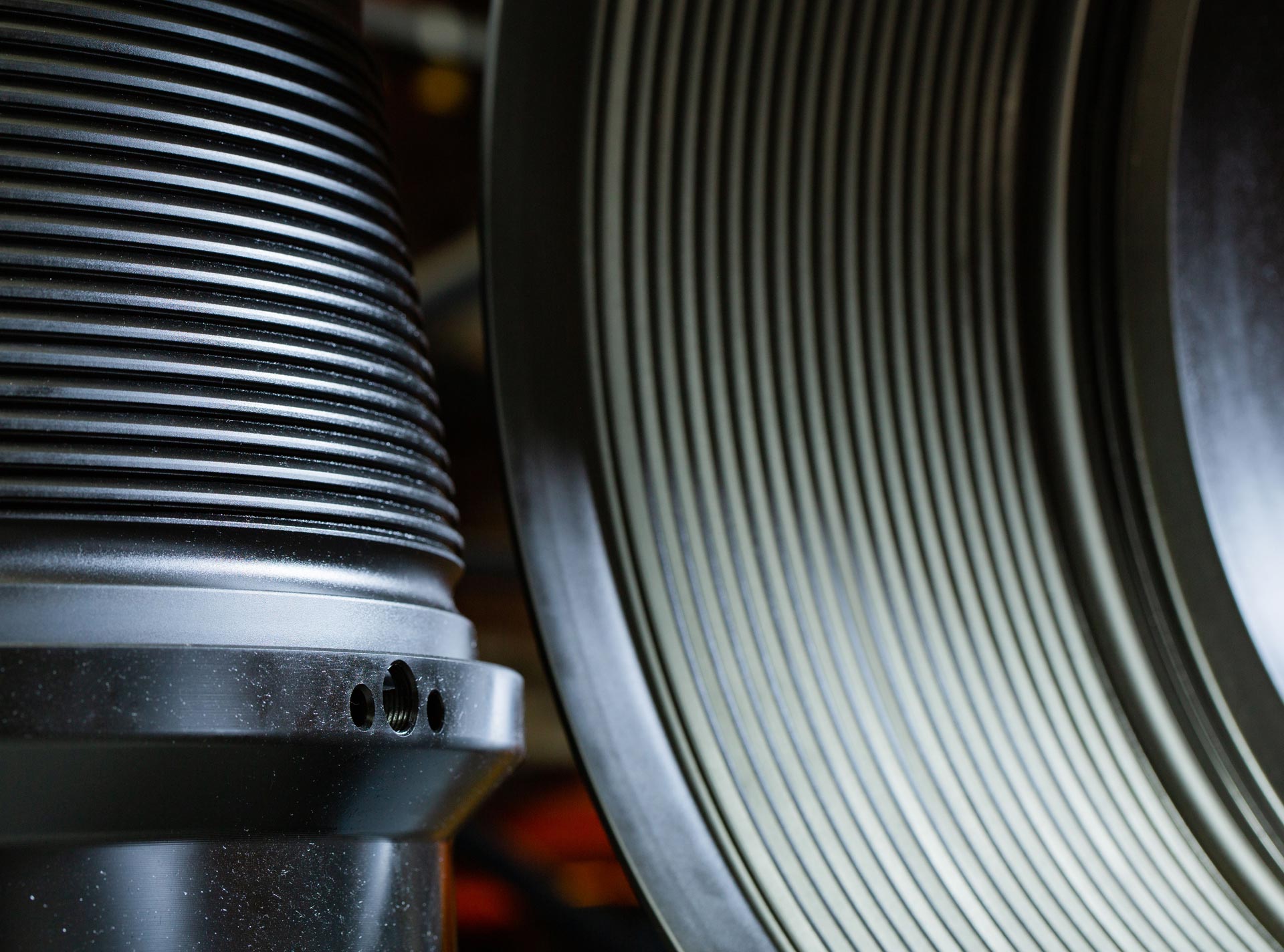

Viper Connectors

Proven performance in deepwater and ultra-deepwater applications.

As the most extensively tested large-diameter connectors on the market, Viper™ weld-on connectors are ideally suited for extreme-service conductor and casing applications. Available in 16- in. to 42-in. diameters, Viper connectors are rated at or greater than 100% of pipe body for internal and external pressure, tension, compression, and bending capacity in most sizes. The patented ViperLock™ anti-rotation device is easy to install and is reversible.

- A true multipurpose connector suitable for most applications

- Deepwater subsea well conductors or jet strings

- Platform conductors or drive pipe

- Jackup exploratory well conductors

- Tieback conductors

- Intermediate and surface casing strings, including deviated wells

- Deepwater casing strings run in open water

Viper features a weld-on pin and weld-on box design. Viper connectors in sizes up to 34-in. diameter feature a near-flush inside diameter (ID) profile and an upset outside diameter (OD) that serves as an integral lift shoulder.

Viper connectors have a dual-seal design: an elastomeric O-ring as the primary seal and a secondary metal-to-metal seawater exclusion seal. Extensive finite element analysis and physical testing have been used to verify performance capacities across the Viper product line.

Two thread configurations are available. The Viper-1ST connector makes up in approximately 1.75 turns, and the Viper-3ST connector makes up in just over half a turn. Makeup torques range from 50,000 to 70,000 ft-lb depending on size. Viper connectors are suitable for makeup with either power tongs or manual tongs.

The CAL I-E qualification requires the testing of two samples:

- The first sample (ISO Specimen 1) is machined to an extreme tolerance, worst-case sealing configuration and make-and-break tested. Upon completion, seal performance of this sample is then verified through a series of tests that include two-quadrant combined load with bending (ISO Series B), four-quadrant combined load (ISO Series A), and limit load to failure.

- The second sample (ISO Specimen 5) is machined to an extreme tolerance, worst-case galling configuration. This sample then undergoes make-and-break testing.

Features/Benefits

- Connector ratings meet or exceed full pipe body strength in most sizes

- Reliable performance under extreme loading conditions

- Full pedigree of analysis and test data

- Extensive analysis and full-scale testing data support connector ratings

- Fatigue rated and tested

- Designed and fully tested for excellent fatigue performance

- Dual-sealing design

- Elastomeric O-ring primary seal and metal-to-metal seawater exclusion seal

- Three capture features

- Hooked threadform, OD capture feature, and tapered load shoulder effectively eliminate thread jump-out under extreme loading conditions

- ViperLock anti-rotation device

- Patented design is reliable, easy to install, reversible, and fully tested

- Engineered weld neck

- Longer connector weld neck moves the weld to a low stress area

Tested Sizes

- 20 × 0.625 × 80 in. GP-95 Viper-1ST

- 22 × 1.000 × 80 in. GP-95 Viper-1ST

- 22 × 1.250 × 80 in. GP-95 Viper-1ST

- 22 × 1.500 × 80 in. GP-95 Viper-1ST

Viper Connectors Product Summary Flyer

Viper High-Performance Weld-On Connector Flyer

XL Systems 22×0.625 X80 GP 95 Viper Connector Gas Data Sheet

XL Systems 22×1.00 X80 GP 95 Viper Connector Gas Data Sheet

XL Systems 22×1.25 X80 GP 95 Viper Connector Gas Data Sheet

XL Systems 22×1.50 X80 GP 95 Viper Connector Gas Data Sheet

Viper Connector Fatigue Test Summary Technical Summary

Viper Connector Physical Testing Program Technical Summary

Viper Connector Bolt-On Lift Ring Technical Summary

ViperLock anti-rotationx

Related Products

XLW Connectors

Combining the integrity of a wedge thread connector with the strength of a weld-on connector.

XLW-GT Connectors

Gas-tight internal metal seal designed for high performance under gas pressure loading.

Related Tools

XL Systems Specs Direct

Specs Direct provides standard connector performance data sheets for the most common pipe and connector configurations offered by XL Systems.

Related News

Viper connector delivers proven fatigue performance in deepwater and harsh environments

Unprecedented testing verifies the weld-on connector's strength and sealability.