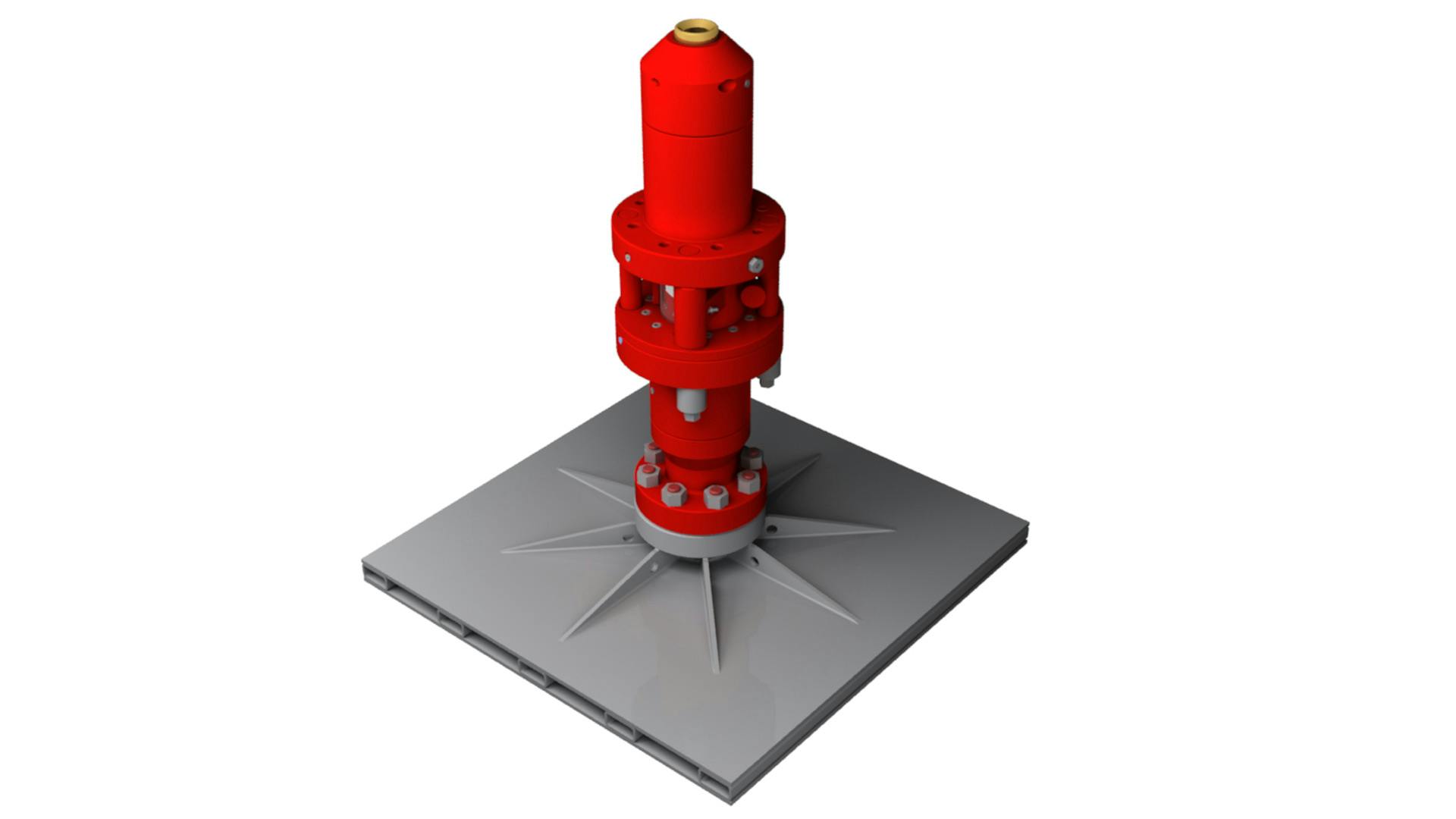

Over/Under Stripper Assembly

The Texas Oil Tools over/under stripper assembly has two independent packers that are compressed by independent pistons.

Suitable for various applications and working environments where two pack-off barrier systems are required, the Texas Oil Tools™ over/under stripper assembly continues to lead the industry in reliable well control safety equipment.

Our DSV, DSU, and DSN series over/under stripper assemblies incorporate two independent packers that are compressed by independent pistons. This setup allows for an overall shorter stack height and reduced weight.

Utilizing these independent pistons, you can use one packer while the other is held in reserve. When the first packer cannot affect a seal, the second packer is actuated, thus extending the time between packer changes. In addition, the side-door design provides ease-of-maintenance and accessibility to the pack-off element and bushings, allowing them to be replaced under pressure.

Our newest model, the DSN, features a 5-in. thru bore design, allowing for larger OD coiled tubing and bottomhole assemblies (BHA) to be run.

Features/Benefits

- Compact profile allows for an overall reduced stack height and weight

- Pressure chamber between the packers can be used to inject lubricants or inhibitors during coiled tubing operations, extending the packer's life

- Independent hydraulic pistons allow independent operation and service of packers; snub into well with either packer

- Extended wear bushings reduce the unsupported distance between injector blocks and stripper assembly

- Field-proven and enhanced design replaces outdated side-door and tandem side-door packers

- Side-door design provides ease-of-maintenance and accessibility to the pack-off element and bushings, allowing them to be replaced under pressure

- Dual barrier pack-off design increases safety

Applications

- H2S service: -20°F to 250°F (-29°C to 121°C)

- North Sea service: -25°F to 200°F

- Arctic: -50°F to 200°F

- Steam: 75°F to 500°F

WCE Recertification, Inspection, and Repair

When it comes to well control equipment (WCE), you can never be too safe. With increasingly stringent industry standards around documentation and recertification of equipment, you can rely on our industry-leading engineering, manufacturing, and service centers to maintain compliance.

Product Updates and Bulletins

Sign up to automatically receive the latest product updates and bulletins available for your well control equipment. For instructions on setting up your subscriptions, view the step-by-step directions.

Need assistance? Contact us at [email protected].

Related Products

Pressure Control Accessories

ATP Coiled Tubing

The Quality Tubing ATP coiled tubing uses state-of-the-art thermal processing throughout the manufacturing process to achieve the most advanced coiled tubing product available on the market.

Intervention and Stimulation Aftermarket Solutions

Reduce total cost of ownership of your coiled tubing, stimulation, acidizing, wireline, sand handling, and cementing equipment with our aftermarket solutions.

Related Tools