Oil Separation and Stabilization

We provide complete separation, dehydration, and desalting solutions for crude oil.

Whether we provide individual technologies, packages, complete process systems, or operational support for oil separation and stabilization, our objective is the same: We work closely with our customers to identify the best solution for them. We provide advice and technologies based on deep product expertise and hands-on field experience and provide equipment at a reasonable price that will work as promised.

Our experience spans from onshore to offshore processing, fixed platforms to FPSOs, heavy oil to condensate treatment, and upstream to refinery applications.

High efficiency separator internals

Our separator internals maximize the performance of horizontal separators, slug catchers, flare gas knockout drums, degassers, and gas scrubbers. We understand the risk of damaging an expensive gas compressor with cheap scrubber internals.

We study, design, and produce high efficiency internals for both new separators and for retrofit of old separators in operation. Our expertise in upgrading existing equipment is something we consider unique. We find solutions to typical operational problems by implementing retrofit experience and differentiating product designs. Lessons learned are incorporated in our design practices to ensure that new project deliveries benefit from past field experience.

All removable internals are delivered with professional arrangement drawings and detailed instructions for how to perform the assembly and installation inside the pressure vessel.

ePackTM

Double your oil production or reduce water carryover from the separator to less than half. The ePack is an electrostatic plate pack coalescer, which can be built into new or existing gravity separators to improve the oil-water separation process. Electrostatic separation is commonly used in industry for removing residual water from oil. The ePack and its unique design features now makes it possible to perform electrostatic separation reliably also with presence of gas and large quantities of water. The technology will dramatically increase the separation efficiency which can increase oil throughput, reduce water carryover, reduce cost of heating, and reduce size of processing equipment.

CECTM

The compact electrostatic coalescer (CEC) technology is a small, lightweight flow-through system that increases the size of water droplets dispersed in petroleum oil, greatly enhancing the separation performance in a downstream gravity separator.

Electrostatic treaters

We provide onshore and offshore projects with solutions for electrostatic dehydration and desalting of crude oil. We have developed an intelligent digital application on our Process Intelligence Manager platform, with the objective of providing advice for the most optimal operation of the crude oil desalting process. The many process variables in a crude oil desalting package can be tuned correctly, reaching the salt and residual water specifications robustly at minimal OPEX.

Haewene Brim Case HistoryAdvanced separator internals retrofit facilitates tieback of Brynhild field to Haewene Brim FPSO

CEC Compact Electrostatic Coalescer Data SheetDramatically increases performance of an existing separator

ePack Electrostatic Plate Pack Coalescer Data SheetIncrease production or reduce water carryover from your separator

Noble Energy Case HistoryIntegrated solutions and on-time delivery contributed to expedited first oil for the Dantzler subsea tie back

LLOG Case HistoryLightweight process packages contribute to single topside lift, leading to first oil faster

Ichthys Case HistoryOil dehydration package designed for rough weather conditions at the Ichthys field

P76 Case HistoryReplicated delivery of two stage electrostatic desalter packages

Bellevue Case HistoryScrubber internals retrofit contributes to 40% gas production increase

Separator Internals Data Sheet CollectionData sheets for Side Entry Vane Inlet Device, Top Entry Vane Inlet Device, Cyclonic Inlet Device, Gas Baffle, Slotted Baffles, Perforated Baffles, Plate Pack Coalescer, Vane Pack Mist Eliminator, Sand Pan System, Tore Online Vessel Desanding, Mesh Pad, Demisting Cyclones, and Demisting Cyclone Bundle

Dimlington Terminal Case HistorySlug catcher and scrubber optimization improves performance of Dimlington terminal

Vladimir Filanovsky Field Case HistoryAccessing 1.3 billion barrels of oil with expertise from NOV

ePack Technology Training FlyerTraining in ePack technology, efficient operation, and maintenance

Electrostatic Coalescer and Desalter Training FlyerTraining in Electrostatic Coalescer and Desalter technology and process

Multiphase Separation Training FlyerTraining in Multiphase Separation with gravity separators, scrubbers, and knock-out drums

Var Energi's Jotun FPSO Life Extension Case StudyNOV serves as a preferred partner for brownfield services

Separation and Produced Water Treatment Case StudyDebottlenecking and optimization of platform offshore Malaysia

Process Upgrade Case StudyThree-phase separator retrofit in the North Sea

Compressor Lifespan Improvement Case StudyScrubber retrofit increases the compressor’s lifespan and reduces fouling on North Sea platform

Electrostatic coalescer

ePack installation in separator

Removable vane inlet and mesh agglomerator in scrubber

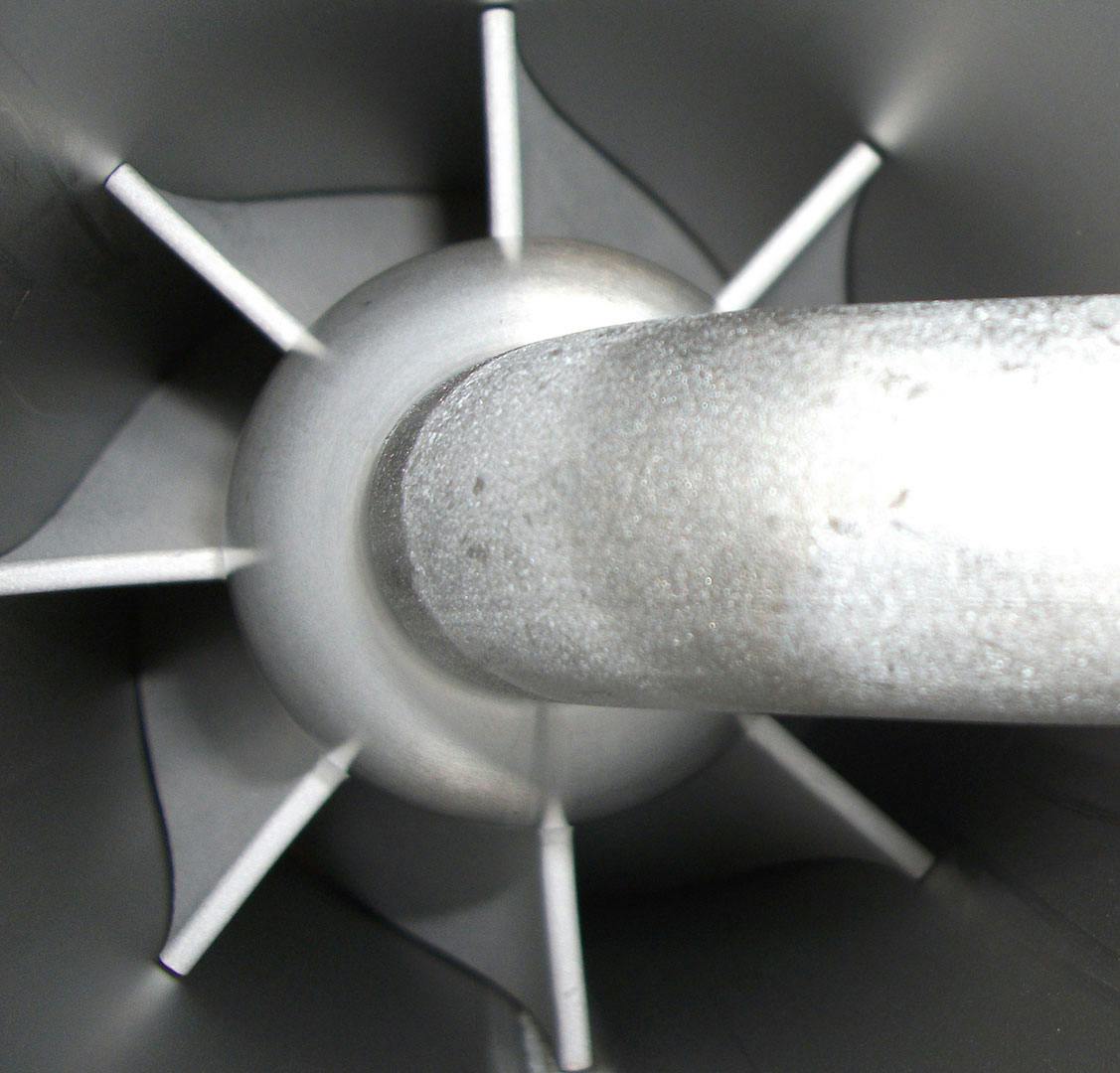

Maximize demisting performance with casted swirl inducers

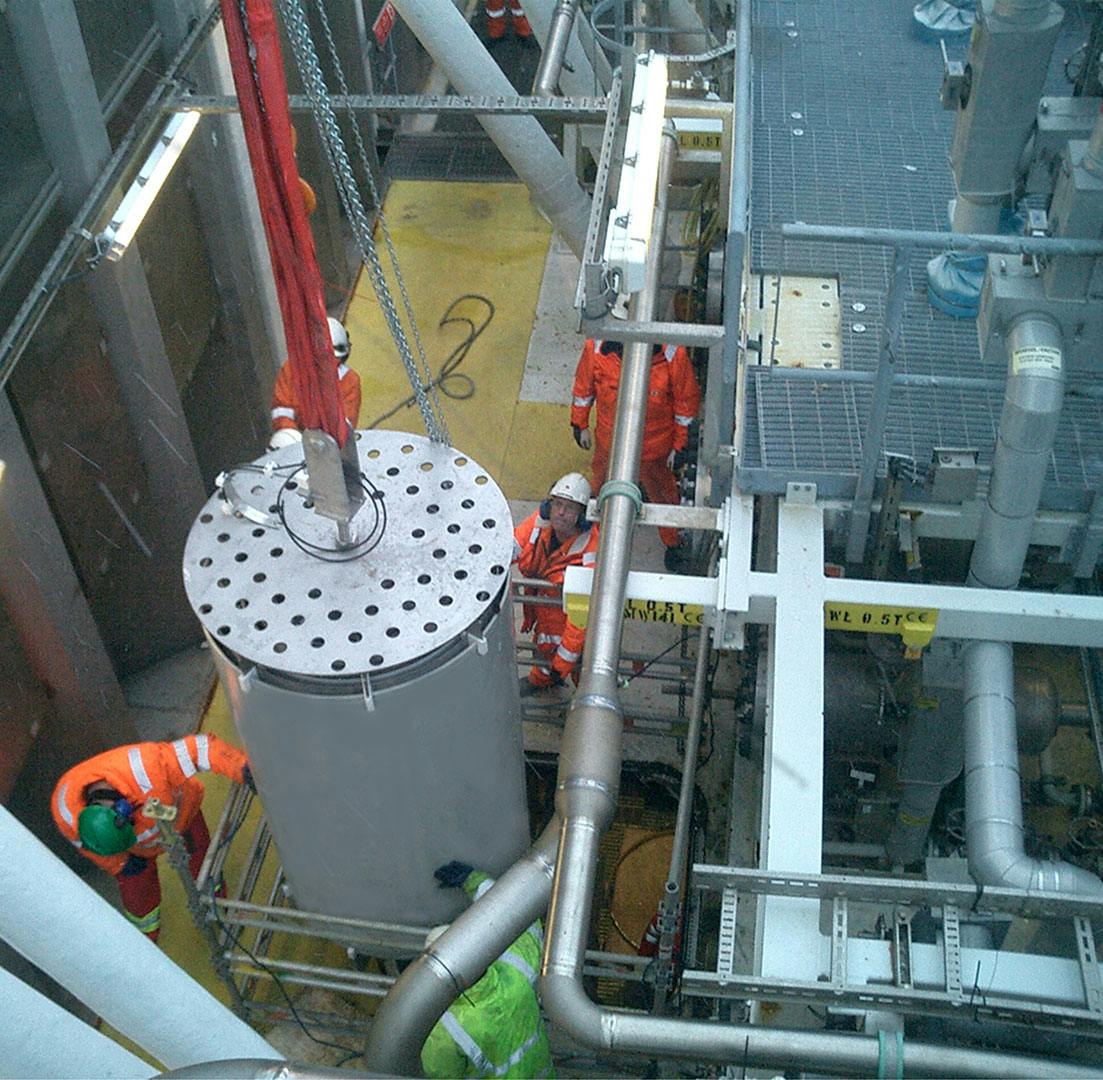

CEC electrode cartridge being installed

The NOV inlet device with diffuser banks will replace your inlet cyclones

Related Products

Process Systems

We deliver equipment and solutions to the upstream oil and gas industry for the separation and treatment of oil, gas, solids, seawater, and produced water.

Produced Water Treatment

Our comprehensive produced water portfolio allows us to deliver safe, compliant, customer-oriented results necessary for responsible energy production.

Solids Handling

Don’t let sand and waste solids get in the way of your production. Our field-proven technologies will integrate seamlessly, taking unwanted solids from production to disposal.

Brownfield Solutions

We optimize process systems, remove production bottlenecks, improve environmental performance, and support operations through a global network of specialists and a commitment to service.

Process Intelligence Manager Crude Oil

Reduce operational costs and satisfy crude oil export requirements with unique insights from our Process Intelligence Manager.