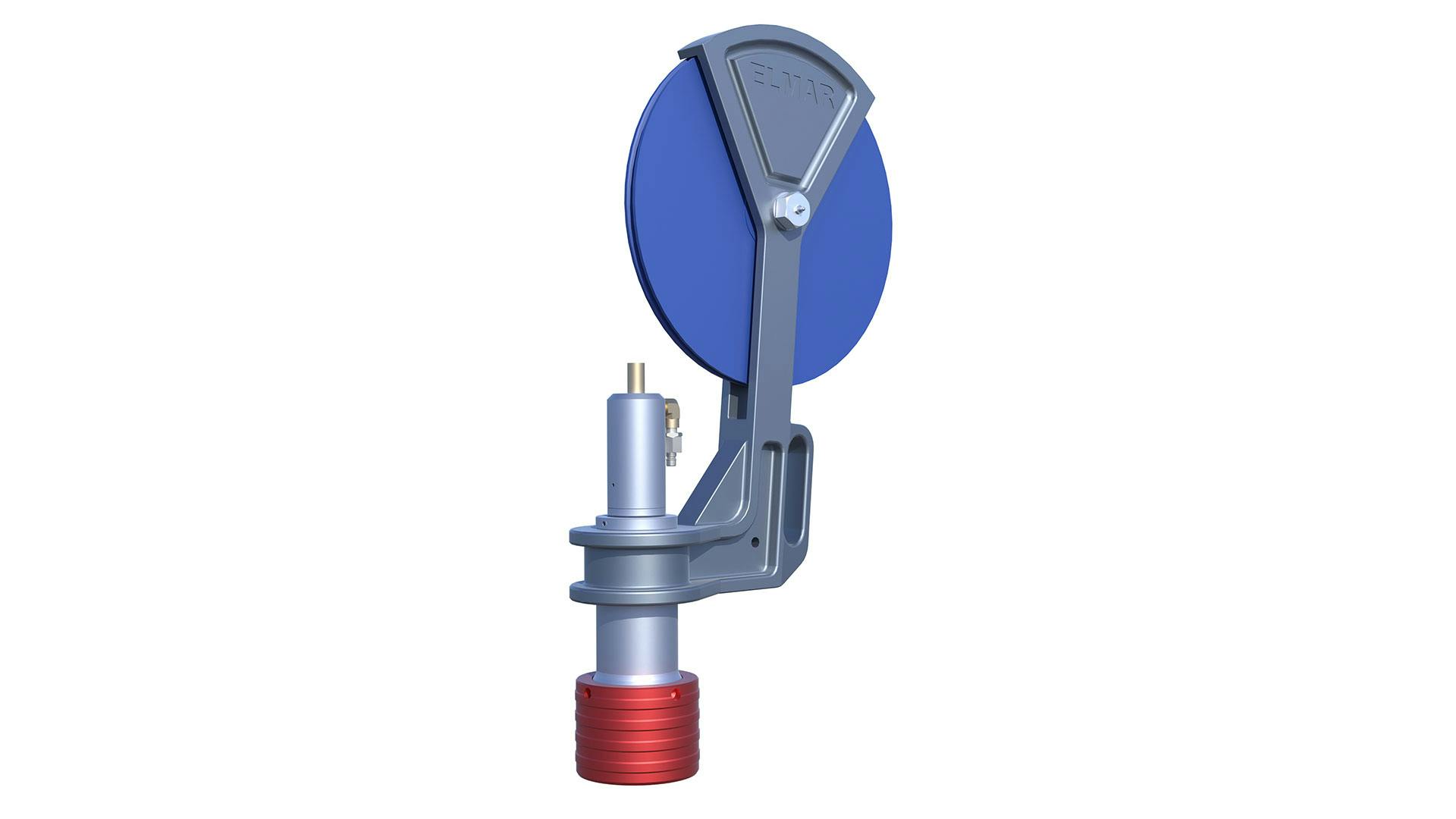

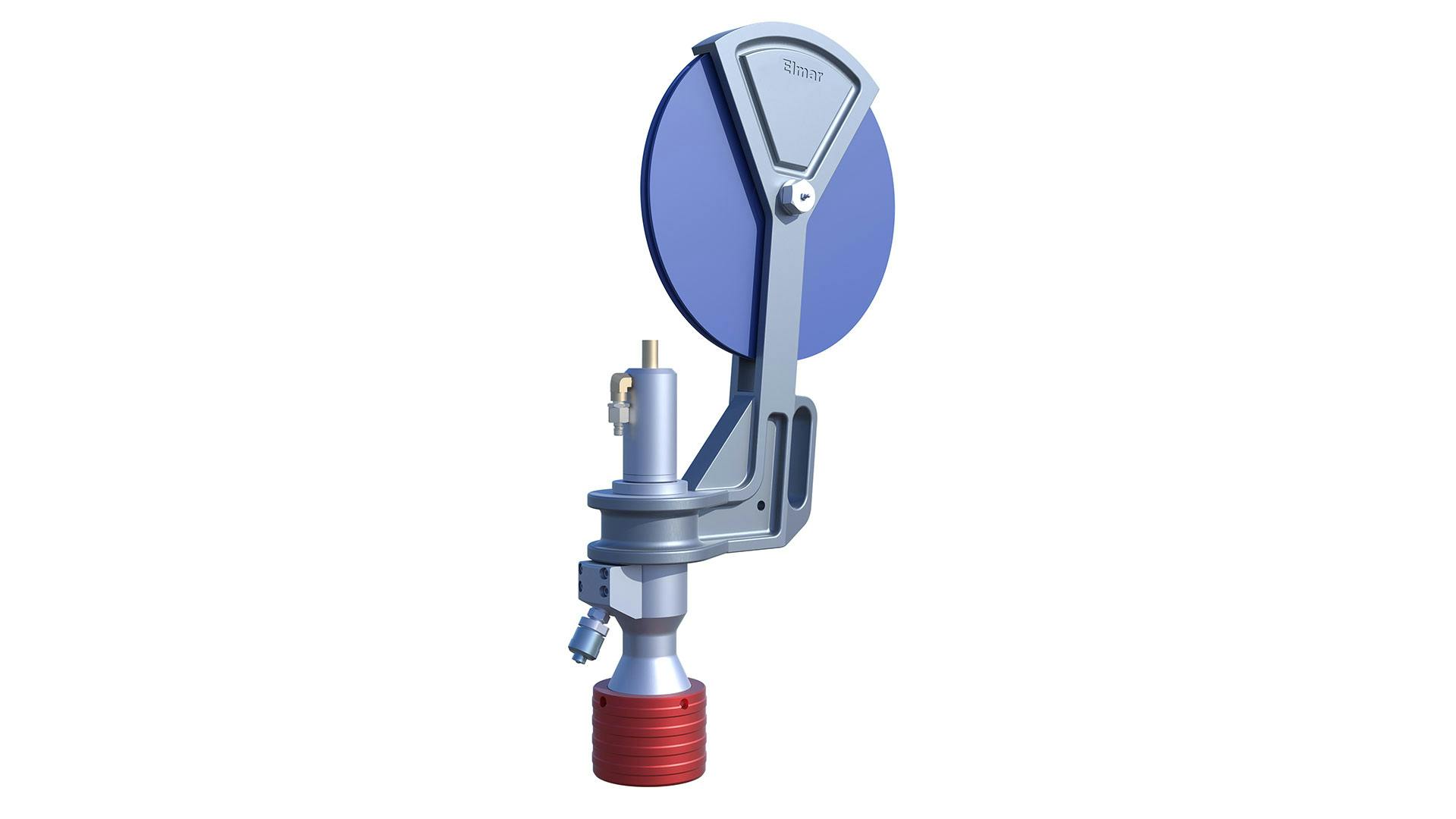

Lightweight Stuffing Box

Lightweight solution for manual handling and simplified operations with remote hydraulic actuation.

Positive protection during well operations.

As the primary well control barrier, the Elmar™ lightweight stuffing box mitigates the risk of hydrocarbon release during slickline well interventions, allowing access to wells under pressure.

Our hydraulic slickline stuffing box is lightweight, compact, and simple to operate and has been designed to safely and conveniently pack off all sizes of solid wireline up to 0.160 in. and from 5,000- to 15,000-psi working pressures.

Available to suit various well conditions, with selection critical for fluid compatibility and reduced friction of the slickline, our packings are engineered to fit specific line size. This eliminates the need for wellsite reaming and reduces the chance of premature failures due to improper centralization.

Positioned at the uppermost point of the pressure control equipment string, our lightweight stuffing box incorporates a blow-out plug to automatically shut in the well pressure in the event of packing failure or the slickline breaking/being stripped from the rope socket.

This slickline stuffing box consists of a chamber containing packing with an external hydraulic packing nut assembly. The slickline passes through the packing, which can be energized by the hydraulic packing nut to regain a seal when required.

When operational demands require it, this stuffing box can be upgraded to include an integrated ball check valve assembly and chemical/lubrication injection port with felt packing. The injection point increases sealing performance and life span of slickline stuffing box packing, allowing fluid contact with the wireline to combat challenging well conditions.

Related Products

Intervention and Stimulation Aftermarket Solutions

Reduce total cost of ownership of your coiled tubing, stimulation, acidizing, wireline, sand handling, and cementing equipment with our aftermarket solutions.

Related Tools