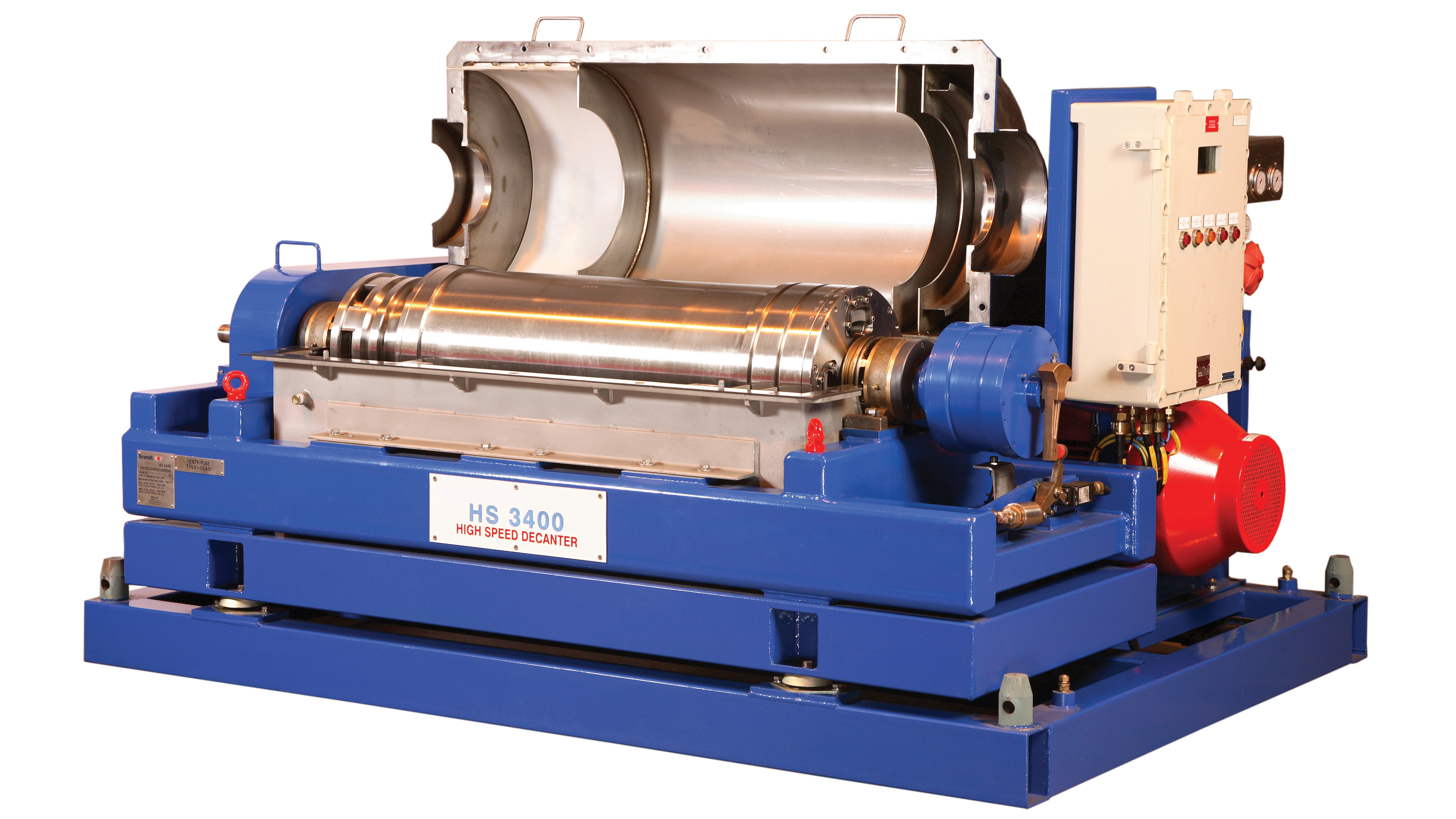

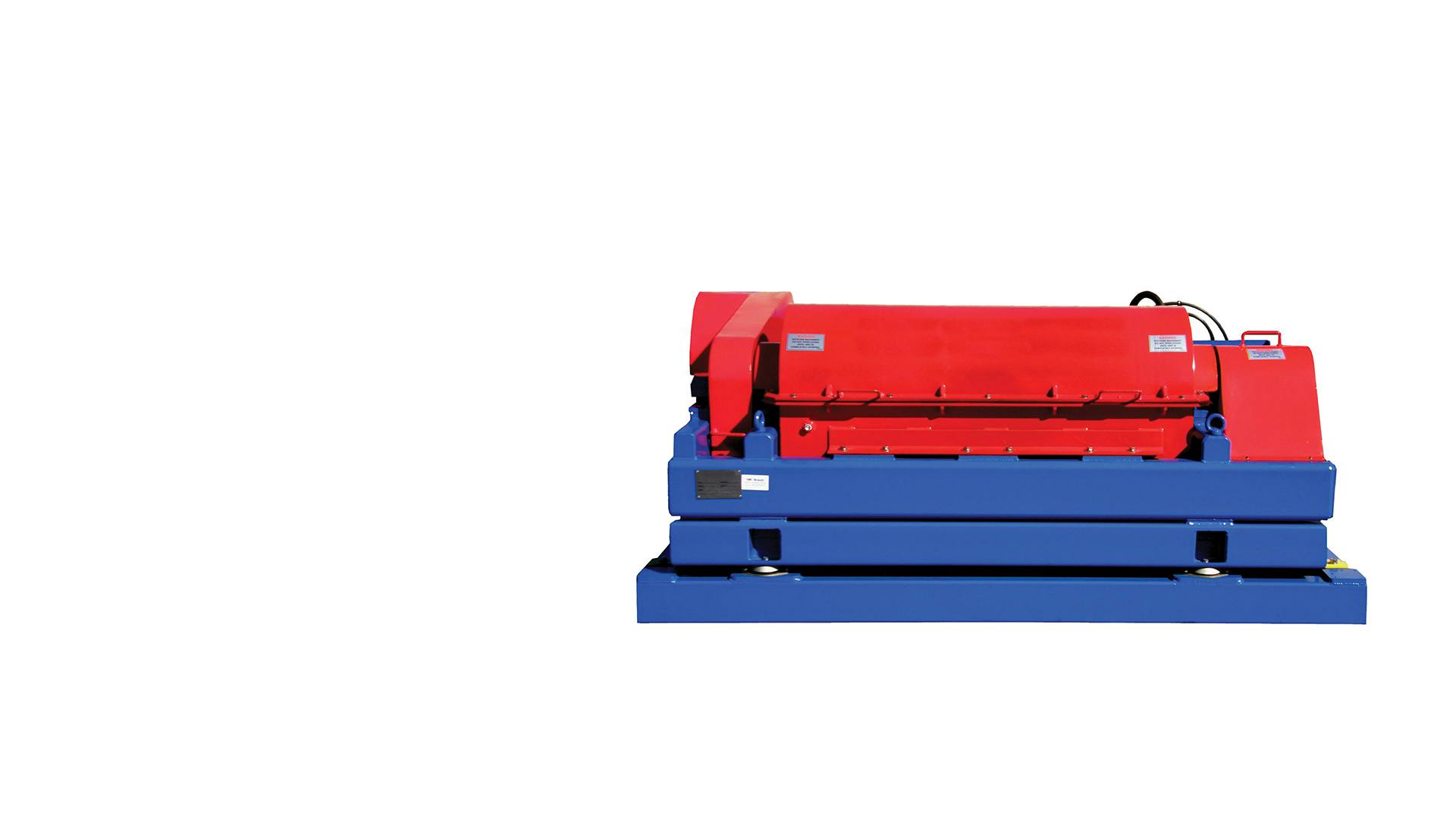

HS-3400 Series Centrifuge

Compact design for maximum performance.

The HS-3400 series centrifuge is fed from the solids end of the conveyor. Mud is introduced into the feed chamber through a feed tube and exits into the bowl via four nozzles. The HS-3400 FS exerts up to 2,275 G’s on the mud, while the HS-3400 VSD, HS-3400 FVS, and the HS-3400 VS exert up to 2,100 G’s.

The HS-3400 FS is a fixed-speed drive unit, whereas the HS-3400 FVS and HS-3400 VS are equipped with variable-frequency drive (VFD) control, which provides a controlled application of motor drive power to the centrifuge components (bowl, conveyor, and feed pump). Hardware and software packages can be custom-designed to specific installation and operational requirements.

The HS-3400 VSD is a hydraulically driven unit with a variable speed bowl drive. The HS-3400 FVS is electrically driven, with both the bowl drive and conveyor equipped with variable speed. The HS-3400 VSD and HS-3400 FVS centrifuges offer increased operational flexibility in situations for which conditions vary.

With a processing capacity up to 200 gal/min (757 L/min), the HS-3400 series centrifuge offers outstanding performance in a wide range of drilling applications and conditions.

Features

- Up to 200 gal/min (757 L/min) maximum processing capacity

- 52:1 ratio planetary gearbox

- Feed from solids end

- VFD control (HS-3400 FVS)

- Bowl and heads manufactured of stainless steel

- Stainless steel case

- Entire scroll fitted with sintered tungsten carbide tiles

- Flush connections

- Case gaskets

- Vibration switch shut-off mechanism (HS-3400 FS, HS-3400 FVS)

- Case baffle gasket

- Torque overload mechanism (HS-3400 FS, HS-3400 VSD)

- Roller and ball bearings

- Sturdy WF-beam skid

- Eight tungsten carbide solids discharge nozzles

- Four epicentric orifices

- Chute style discharge for solid and liquid ends

Benefits

- Ample capacity for use in a variety of drilling applications and conditions (water)

- Provides for a reduced motor size

- Provides a short feed tube with less vibration

- Permits easy adjustment of bowl, conveyor, and feed pump speeds for varying process conditions; provides torque overload protection

- Provides corrosion resistance for long life, smooth operation, and low maintenance

- Offers high strength and corrosion resistance

- Offers abrasion resistance for maximum operational life and low maintenance

- Aids in cleaning excess material from inside the case

- Retains process materials within the case to prevent spills or leaks

- Automatically disables operation in situations of high vibration

- Keeps separated streams apart

- Shuts down both the centrifuge and feed pump in overload situations due to blockage

- Offers long life and low maintenance

- Supplies a solid foundation for smooth operation

- Offers an abrasion-resistant exit of solids from the bowl to discharge. These nozzles are also cost effective during refurbishment, as they can simply be replaced rather than needing costly repairs.

- Enables high discharge flow rate and easy adjustment of the pond depth

- Enables high-capacity processing

BRANDT Centrifuge Spec Sheet

BRANDT HS-3400 Centrifuge Flyer (English)

BRANDT HS-3400 Centrifuge Flyer (Arabic)

BRANDT HS-3400 Centrifuge Flyer (Brazilian Portuguese)

BRANDT HS-3400 Centrifuge Flyer (Spanish)

BRANDT HS-3400 Centrifuge Flyer (French)

BRANDT HS-3400 Centrifuge Flyer (Russian)

BRANDT HS-3400 Centrifuge Flyer (Chinese)

Related Products

HS-1960 Centrifuge

The HS-1960 centrifuge fuses high efficiency and compact design for maximum performance and effortless operation.

HS-2000M Centrifuge

The HS-2000M centrifuge uses high G-forces to separate fine solids from liquid.

HS-2172 Centrifuge

As the most innovative decanting centrifuge available, HS-2172 maximizes performance, efficiency, and operational simplicity.