GSP II Liner Hanger

Designed for deviated and horizontal holes. Available in both mechanical and hydraulic options.

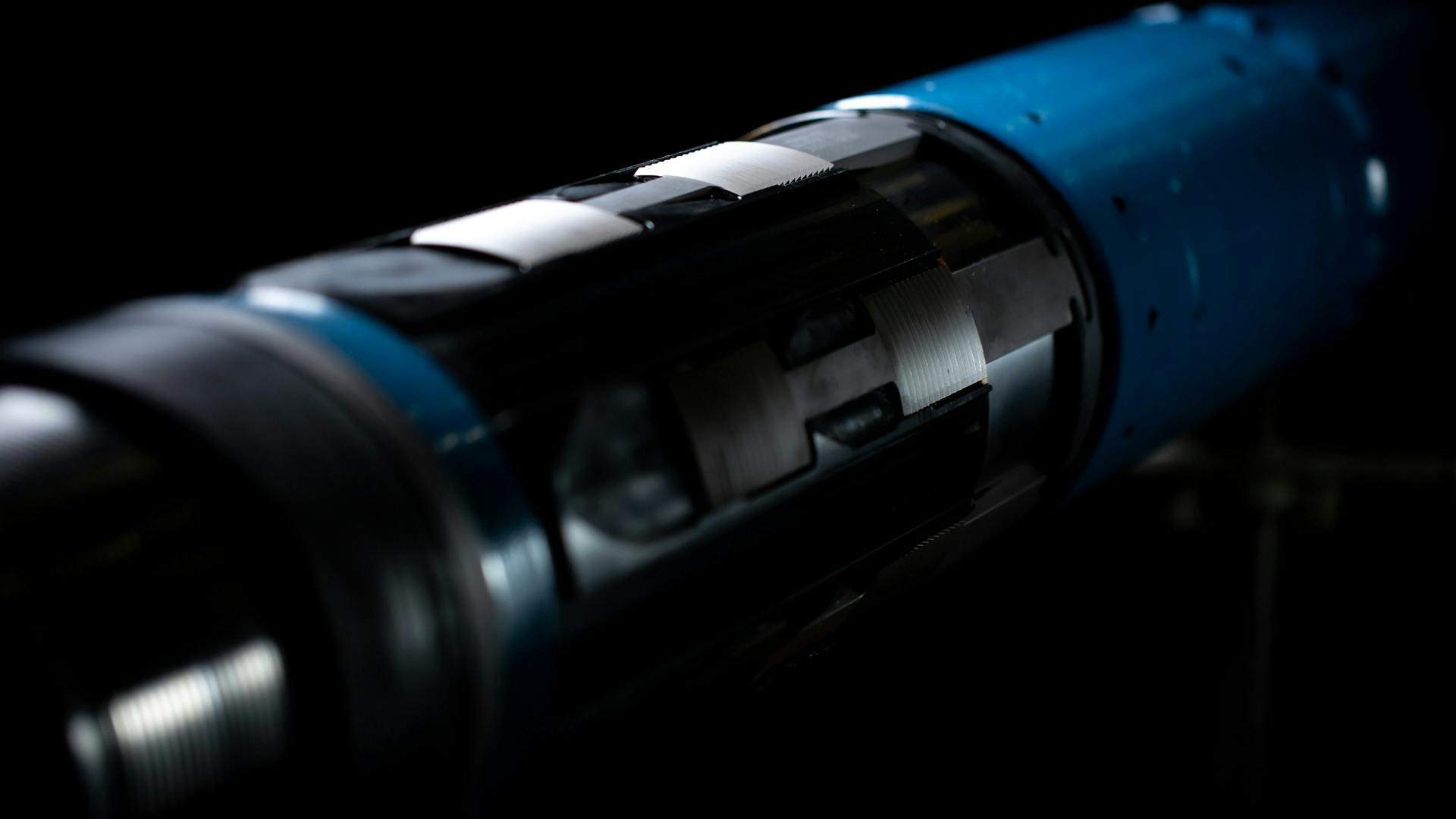

GSP II Hydraulic Set Liner Hanger

Designed for deviated and horizontal holes, the GSP II hydraulic-set liner hanger contains slips that are fully recessed into a special profile at the rotating body. This ensures trouble-free installation and uniform load distribution in the setting section. In set and non-set state, the GSP II liner hanger allows a very high bypass, ensuring a high flow rate with low pressure loss.

Hydraulic liner hanger design features

- All hydraulic seals remain stationary during rotation of the liner

- Improved seal stack in the hydraulic cylinder; HP/HT seals

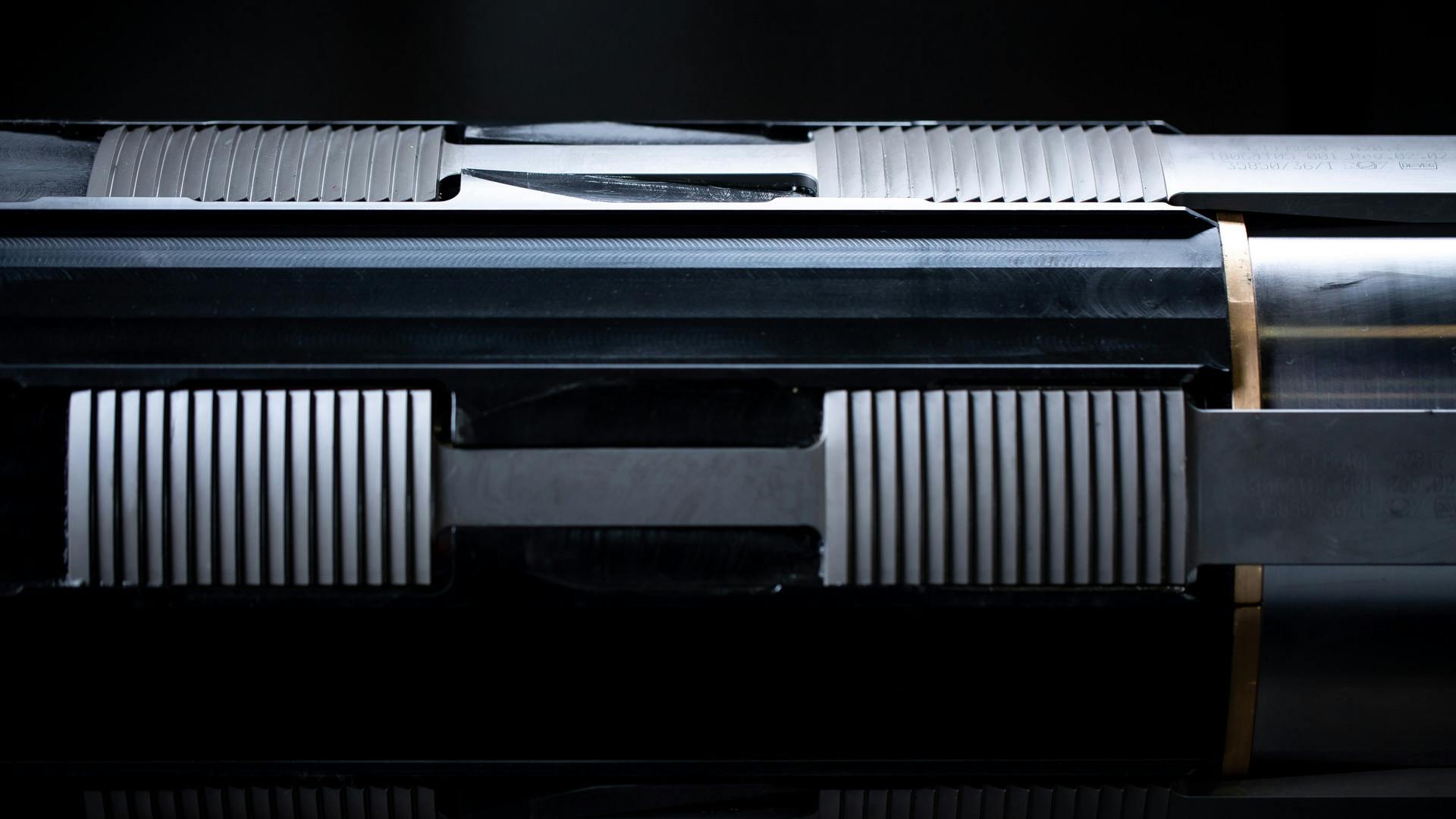

GSP II Mechanical Liner Hanger

Designed for vertical and slightly deviated holes where rotational string manipulation is possible, the GSP II mechanical set liner hanger contains fully recessed slips, ensuring trouble-free installation and uniform load distribution in the setting section. The GSP II mechanical liner hanger utilizes a solid one-piece body that is not compromised by a hydraulic cylinder or any ports. Thus, allowing the liner hanger to have an overall enhanced performance rating that matches or exceeds the customer’s casing mechanical properties. In addition, the GSP II mechanical liner hanger allows a very high bypass area, ensuring a high flow rate with low pressure loss.

Mechanical liner hanger design features

- Enhanced overall performance ratings due to no need for hydraulic cylinder or hydraulic seals

- Standard right-hand mechanical set and release with left-hand option available upon request

GSP II features and benefits

- Non-weld design, one-piece body with premium threads

- Slips are fully recessed and pocketed into a special profile at the rotating body to prevent from premature setting during running

- Slips and cone are designed to minimize casing stress

- Slips are designed and tested to hang inside a large range of casing weights

- Capable of hanging long, heavy liners with enhanced hanging capacity

- Large annular flow area in set and unset position

- Lock of slips prevents premature setting during running

- Rotating/non-rotating (optional)

Materials

- L80, T95, P110, Q125, 22Cr 125 ksi

- Other materials on request

Thread connections

- Standard VAM® TOP/VAM® 21 or on customer’s request

GSP II Liner Hanger Tool Specification

GSP II Mechanical Liner Hanger Spec Sheet

Successful Germany Geothermal Liner System Installations Case Study

Longest and Heaviest Geothermal Liner Hanger Installation Case Study

Permian Liner Hanger System Success Case Study

Successful Offshore Caspian Sea Liner Hanger Installation Case Study

Geothermal Well Construction Products Brochure

Sustainable Greenhouses Hoogweg Case Study

Geothermal Technologies

We have specialized in geothermal technologies for more than a decade, with experience in completing wellbores in hundreds of geothermal installations for projects ranging from heating villages in small communities to highly prolific electrical generation and heating projects for farming communities, regional governments, and major international companies. We have extensively supported the geothermal industry with more than 220 successful geothermal-specific liner hanger systems and well construction installations for more than 50 customers in nine countries, proving that we understand the unique conditions and challenges for geothermal applications and regularly provide solutions to meet these needs.

Related Products

VXP Liner Top Packer

Developed for high differential pressures, the VXP liner top packer is also ISO 14310/14998 V0 certified.

SURESET Liner Hanger Packer

Complete liner hanger system built on a one-piece mandrel with no internal connections

GSL Liner Hanger

Designed for tight clearance, our GSL liner hanger assists you in hanging an intermediate liner.