Bulldog Frac System

Eliminates wellbore restrictions, allowing operators to push the limits of each treatment and maximize productivity

Versatile, robust means of conducting an annular stimulation through Bulldog frac sleeves

The Bulldog™ frac system is a method of conducting a multistage completion, which allows operators to locate, shift open, isolate, and stimulate each stage with the help of a multiset packer. The system consists of a Bulldog Frac Sleeve installed throughout the casing, and the Bulldog Frac BHA that can selectively open each sleeve allowing them to be treated.

Bulldog single-open (SO) frac sleeve

The Bulldog frac single-open (SO) sleeves feature a mechanical-shift, single-open sleeve designed explicitly for horizontal multistage land applications. The stimulation is conducted by pumping down the coiled tubing annulus using a proprietary BHA. Pumping down the coiled tubing annulus permits higher pumping rates and allows for a better understanding of fracture geometry and dynamics. The Bulldog frac sleeve is compact, light, and easy to handle, which improves makeup times and reduces safety risks.

Bulldog multi-open/close sleeve

The Bulldog frac multi-open/close (MOC) sleeve technology features a mechanical shift and multiple open-and-close sleeves designed explicitly for horizontal multistage completions. The sleeve, along with the BHA design, allows for flexibility with fracturing operations. Treatments can be performed as "open-frac-close" or "open-frac." The MOC feature permits closing sleeves later, should well conditions dictate.

Bulldog dual-shift frac sleeve

Our Bulldog dual-shift (DS) frac sleeve technology features a mechanical shift, multiple-open-and-close sleeve designed explicitly for extended-reach horizontal multistage completions. In most extended horizontal applications, a sufficient downward force is limited. The Bulldog DS frac sleeve requires only upward movement to open and close, providing a reliable means of stimulation.

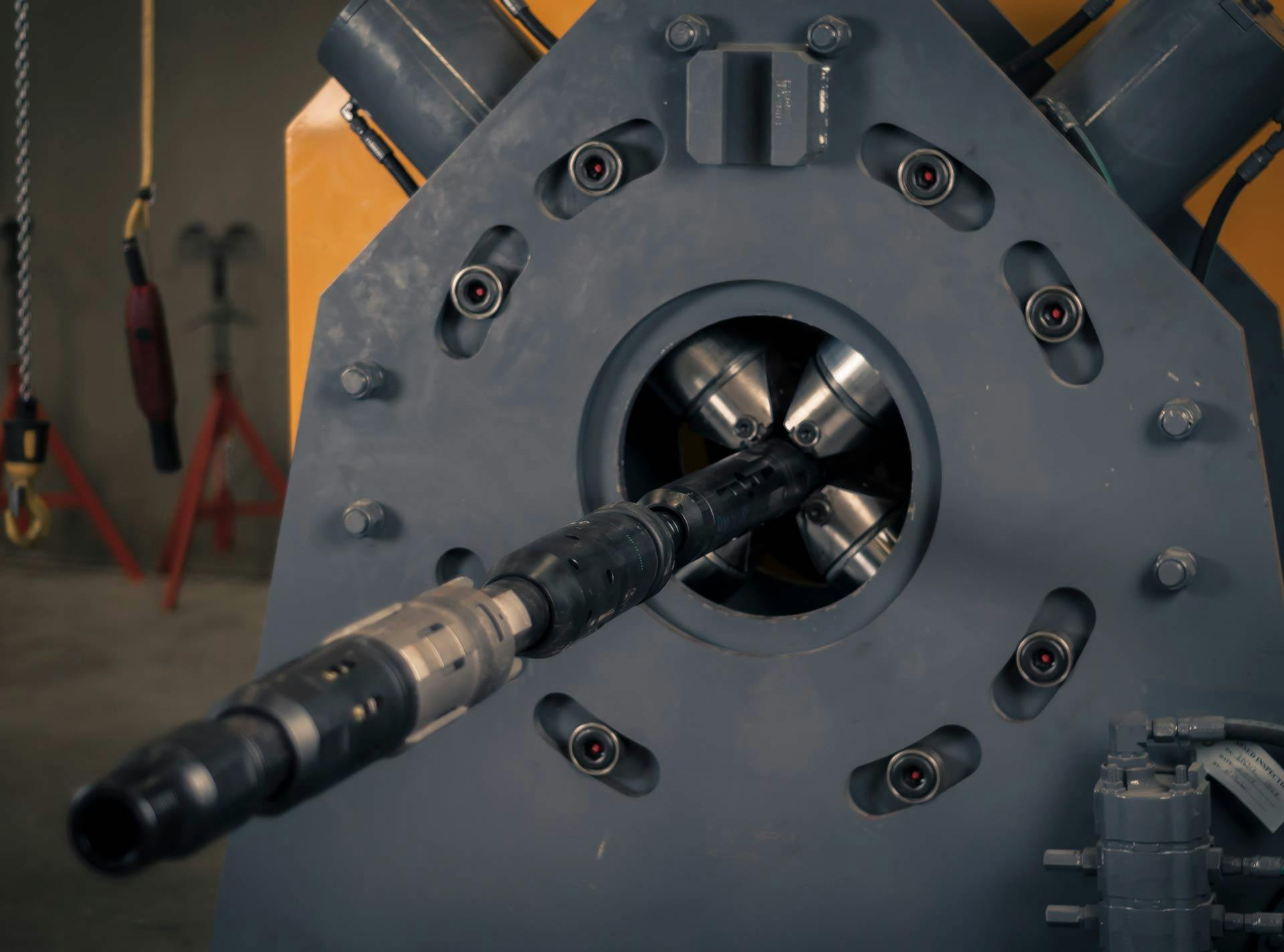

Bulldog annular frac-shifting BHA

The Bulldog frac BHA is bred from offshore heritage, using the field-proven locating and shifting capability of the i-Shift, teamed with our best-in-class coiled tubing straddle frac and abrasive jet components. The payoff is a modular, robust, and reliable means of conducting cost-effective annular frac stimulations. The Bulldog frac BHA is designed specifically for all land-based operations.

Bulldog ball-drop multi-open/close (BD MOC) sleeve

The Bulldog ball-drop multi-open/close (BD MOC) sleeve is a ball-drop activated multistage frac system featuring a mechanical shift, multiple-open and close sleeve designed for horizontal completions. Multiple sleeves can be installed in the completion string, with each sleeve opened with a specific size ball pumped from the surface. The multi-open-close feature permits opening or closing sleeves after the millout of the ball seat should well conditions dictate.

Publications:

Features

- Each sleeve provides accurate depth location during the shifting operations

- Field-proven i-Valve shifting profiles and seal

- Compact, lightweight, and robust

- Fully compatible with cemented and open-hole completions

- Multi-open-close functionality through mechanical shifting tools

- Can be Ball-drop operated with Drillable cast iron ball seats for easy millout

- Compatible with dissolvable ball technology

- BHA includes two memory gauges (located above and below the packer) and its slim design improves clearances over the industry standard

- BHA’s modular concept allows compatibility with all Bulldog frac sleeves

Benefits

- Increased pumping efficiency and rate with a slim design

- No stage count limitations

- Abrasive perforation contingency allows for "on-the-fly" increase to the number of stimulated intervals

- Uses the dead leg for fracture diagnostics

- Safer, simpler, and more efficient handling on the rig floor

- Patented and field-proven sealing system offers full pressure testing of closed sleeves even after several years in service

- Closable sleeves give the option to perform future refracturing as required

- Flexibility in frac design - "open-frac-close/open-frac"

- Reliable shifting and active sleeve locating

Applications

- Formations with a high frequency of screen outs

- High stage count stimulation designs

- Wells requiring abrasive perforating

- Acid or proppant stimulations

Related Products

i-Shift Hydraulic Shifting Tool

The i-Shift is a reliable, selective hydraulic shifting tool used in operating sliding sleeves activated by flow at desired depths to open or close sleeves multiple times during the same run.