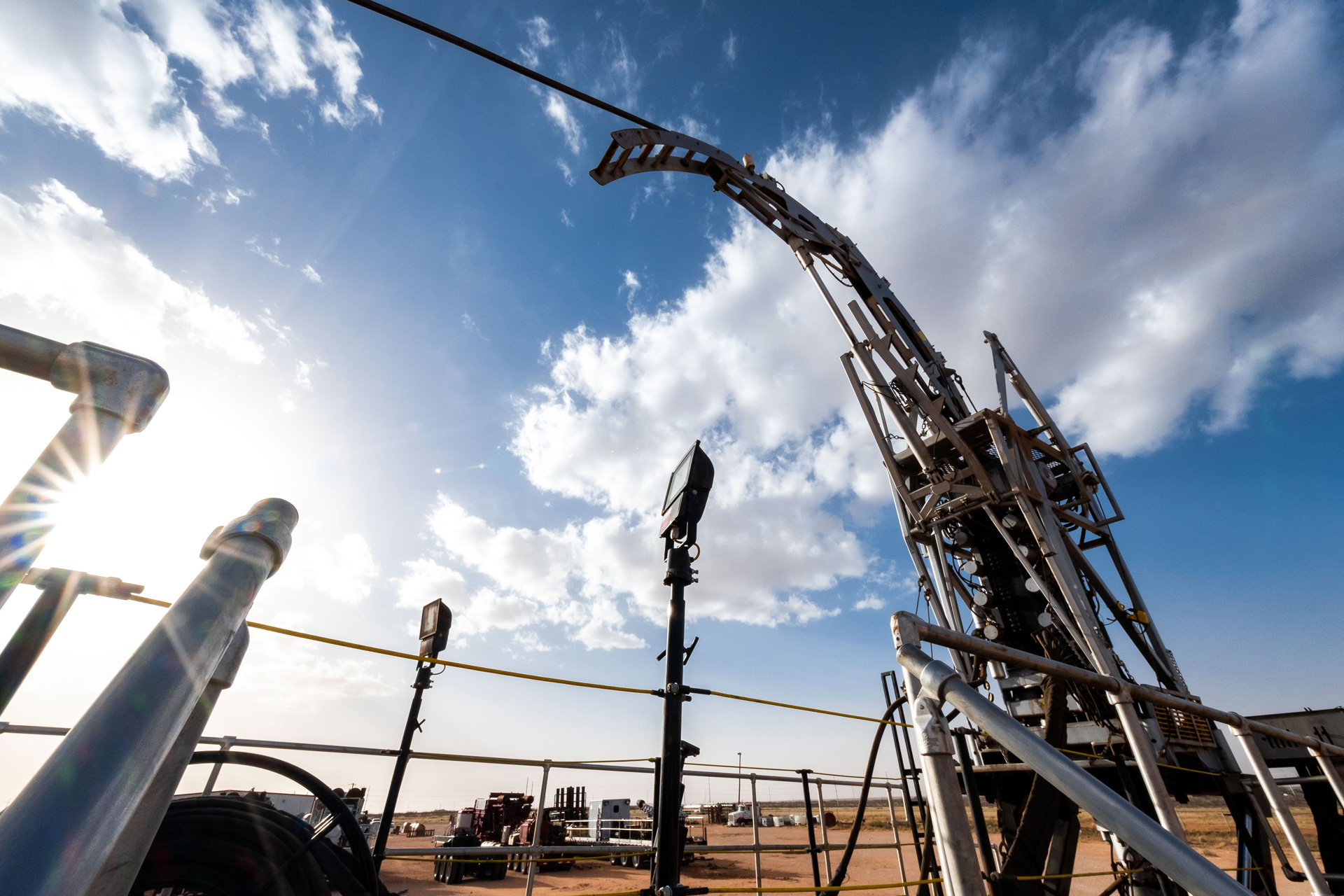

6-Series Injector Enhancements

Advance your coiled tubing operations starting with your injector.

As the leading provider of advanced coiled tubing injectors, we understand the challenges faced in the field while running a complete coiled tubing system. We believe the heart and soul of any coiled tubing system is the injector head, and our line of patented injector enhancements provides solutions to common issues seen while running larger and more rigid pipe.

Many of the technologies are built-in to injectors currently running in the field, and upgrades are also available—regardless of electric or hydraulic injector cabin controls.

Injector chain auto-lubrication system

Improve injector performance through automated chain lubrication processes

With the increased use of larger and stronger coiled tubing strings and overall increased tubing loads, injector chain lubrication is more important than ever. Our Injector Chain Auto-Lubrication (Auto Lube) System increases job reliability by automating the process. This system removes manual operation, ensuring lubrication is applied at appropriate intervals and in complete amounts throughout the job.

Our auto lube system reads the tubing speed from the CTES™ Orion™ data acquisition system or tubing encoder to calculate the chains’ accumulated running feet. The system uses real-time operating data to determine the optimal start time and amount of lubrication while allowing manual intervention by the operator if required.

Hydraulic timing

Simultaneously solves mechanical-timed and fully independent drive challenges

Previous Hydra Rig™ injector generations use a single motor to drive both chains, which results in the front and rear chains advancing at exactly the same number of chain pitches at all times. This causes a conflict with the chains gripping the tubing because the front and rear chains are never precisely the same length, even though they have the same number of pitches. When excessive traction pressure is used and the tension is not increased to compensate, the chains will time at both the tubing and drive system, resulting in the longer chain building up extra length and making the links stack up. The chain must slip microscopically on the tubing to make up the length differences while also gripping strongly enough to hold on to the tubing, which results in a narrowed window of acceptable traction force and increased injector wear.

Our hydraulic timing solution resolves both injector timing issues. Hydraulic timing allows only the traction zone section of the chains to be timed to each other while each chain shares equal load. In operation, the chains constantly shift slowly relative to each other based on the small differences in chain length, eliminating microscopic slipping. This elimination allows for improved gripping of the tubing for equivalent traction forces and extra traction pressure to be added without timing-induced chain stacking issues. Lastly, when tubing slips occur and the chains are no longer timed in the traction zone, hydraulic timing intervenes by keeping the chains close to the same speed, improving the injector’s ability to regain control of the tubing, recover from a slip, and return to normal application.

Strain relief

Relieves accumulated strain between chain and coiled tubing

Forces naturally accumulate between injector chains and coiled tubing as forces are passed, building over longer traction systems. These forces try to make the injector slip. Strain relief allows the grippers to momentarily let go of the coiled tubing, relieving the accumulated strain between the chain and coiled tubing in the long traction sections and improving the traction performance on high-strength heavy-wall coiled tubing. Strain, which accumulates over the traction length, occurs as the push or pull forces are transferred between the tubing and the chains.

Slip mitigation system

Provides immediate increase of injector traction pressure when tubing slip occurs

Our slip mitigation system is engineered to remedy a major pain point—limited operator workforce experience. This system assists operators by providing an immediate increase in injector traction pressure when a tubing slip occurs and can react during an impending slip to prevent a slip from occurring. Today, few strings achieve their potential fatigue life due to mechanical damage caused by slips through an injector, and the slip mitigation system reduces this risk, prolonging string life, reducing downtime, and improving coiled tubing ROI.

Operation

- Uses injector’s hydraulic timing circuit to detect a slip

- While a slip is visible to the hydraulic timing system and is impending—but still imperceptible to the human eye—the slip mitigation system rapidly increases traction pressure to prevent a full slip.

- Slip mitigation system only intervenes during the critical states of an impending slip or a full slip, leaving the traction pressure at the first elevated pressure that is successful to grip the coiled tubing.

- Operators or electronic control systems can observe the system’s rapid traction pressure increase as well as the new pressure setting at the cabin control panel.

Product Updates and Bulletins

Sign up to automatically receive the latest product updates and bulletins available so you stay up to date on your coiled tubing and nitrogen equipment. For instructions on setting up your subscriptions, view the step-by-step directions.

Need assistance? Contact us at [email protected].

Related Products

ATP Coiled Tubing

The Quality Tubing ATP coiled tubing uses state-of-the-art thermal processing throughout the manufacturing process to achieve the most advanced coiled tubing product available on the market.

Two-Door Stripper Assembly

Our DSM and DSW series two-door stripper assembly has two independent elements that can be changed through a side door.

Intervention and Stimulation Aftermarket Solutions

Reduce total cost of ownership of your coiled tubing, stimulation, acidizing, wireline, sand handling, and cementing equipment with our aftermarket solutions.

Related Tools