XLC-S Connectors

Improved structural integrity and fatigue performance.

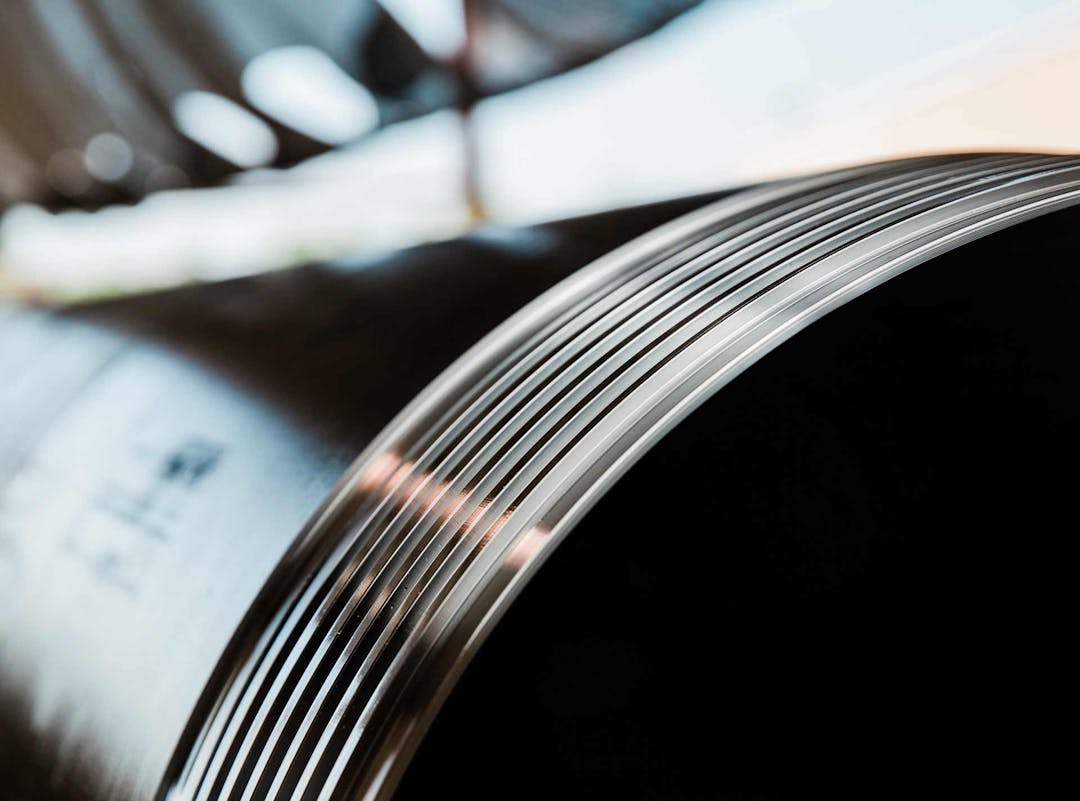

The XLC-S is a second-generation integral connector with pin and box threads machined directly into the pipe wall. This design produces an ideal connector geometry: a true flush inside diameter (ID) and flush outside diameter (OD).

Featuring a wedge threadform with enhanced strength and fatigue performance, XLC-S connectors are ideally suited for conductors and other applications in which both structural integrity and special clearance are critical. XLC-S connectors have an external metal-to-metal seawater exclusion seal, which prevents corrosion in the threads.

XLC-S connectors make up in approximately three turns, the majority of which are low-torque spin-up until the wedge thread surfaces engage. Makeup torques are comparatively low and range from 30,000 to 60,000 ft-lb depending on size. XLC-S connectors are suitable for makeup with either power tongs or manual tongs.

XLC-S connectors have excellent field service history, successfully being used in a wide variety of offshore conductor applications since the late 1980s. XL Systems has completed extensive physical testing of XLC-S connectors, including full-scale fatigue testing and pile-driving testing, and the connectors are manufactured in diameters of 20 in. or more.

Features

- Flush ID and OD profile

- Fatigue rated and tested

- Fully driveable

- External metal seawater exclusion seal

- Integral box and pin threads

- Wedge thread technology

Benefits

- Ideal connector geometry—the connector takes up no more annular space than the pipe

- Comprehensive fatigue testing and analysis data support harsh-environment applications

- Designed and fully tested for drive applications

- Prevents corrosion and corrosion fatigue in the threads

- Cost-effective design eliminates large-diameter forgings and welding costs

- Easy spin-up, high torque capacity, and excellent resistance to anti-rotation

XLC-S Connector

With pin and box threads machined directly into the pipe wall, our XLC-S connector has the ideal geometry. Made up in just three turns, the XLC-S connector is fully driveable and designed for structure integrity.

Related Products

Scorpion Connectors

The latest in our compact class of connectors, Scorpion provides robust strength and proven sealability in deep onshore wells and shallow-water offshore wells.

Related Products

Scorpion Connectors

The latest in our compact class of connectors, Scorpion provides robust strength and proven sealability in deep onshore wells and shallow-water offshore wells.