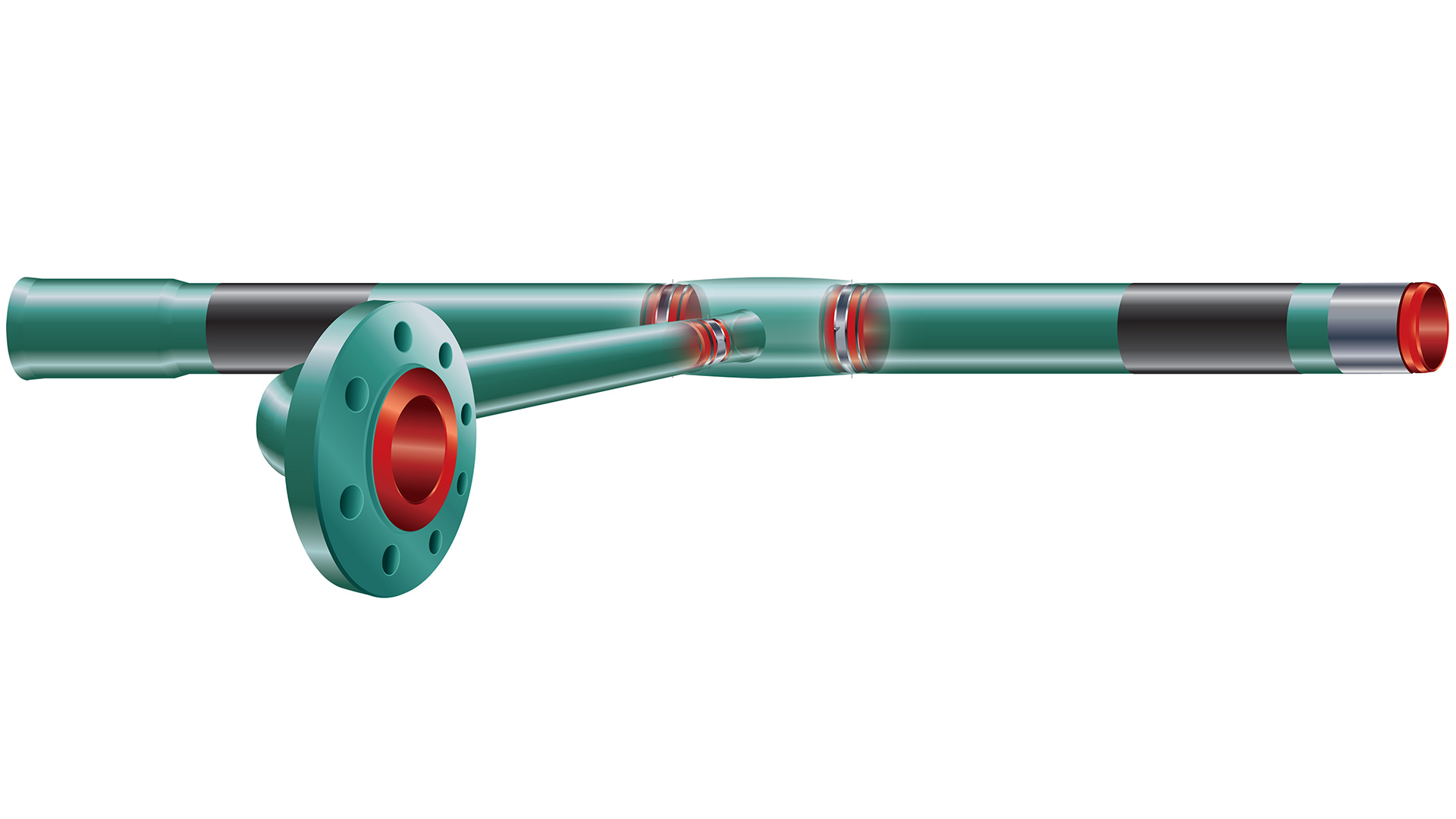

Thru-Kote Connection System

Thru-Kote is a welded connection system for joining internally coated line pipe and piping systems.

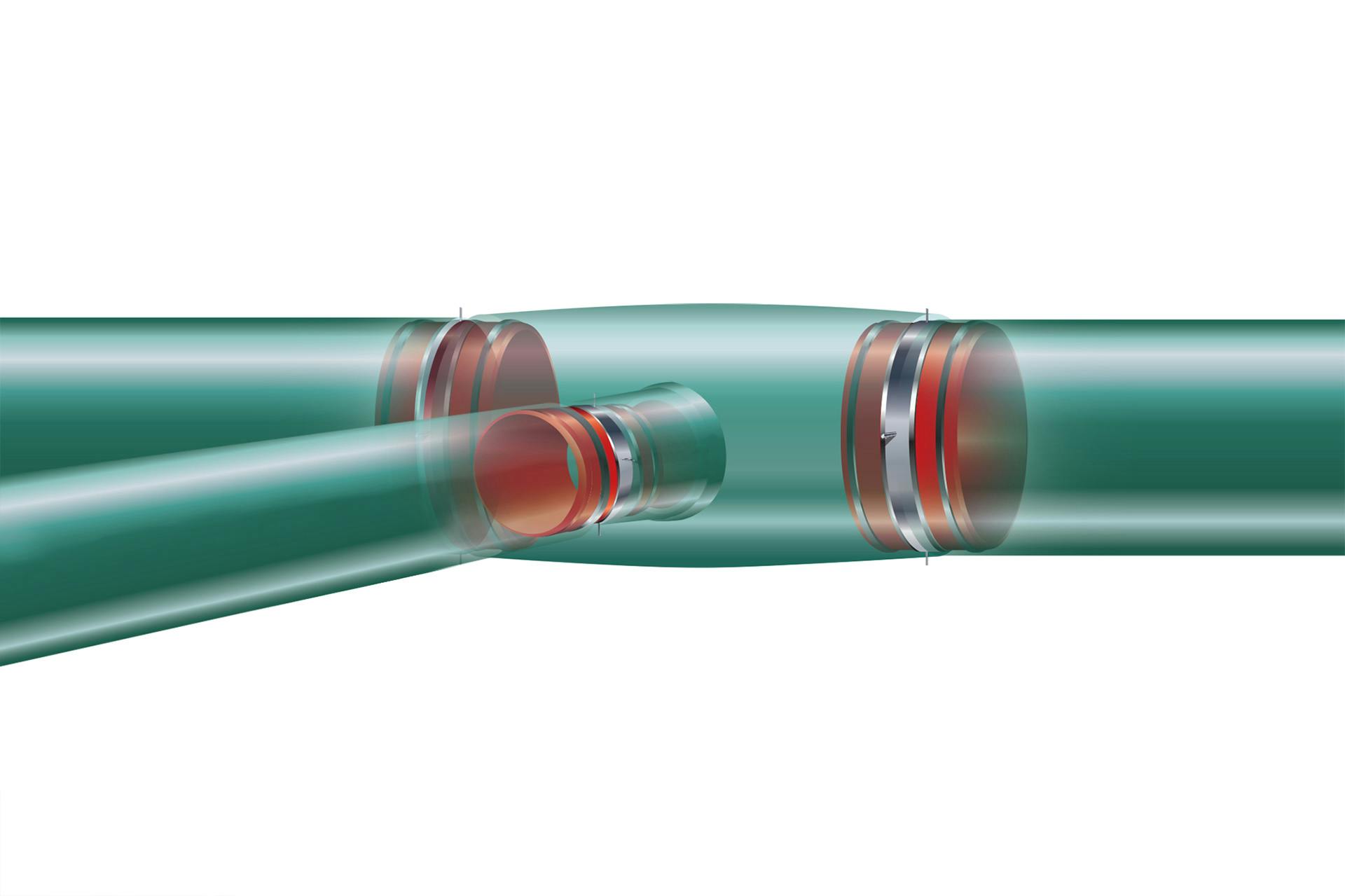

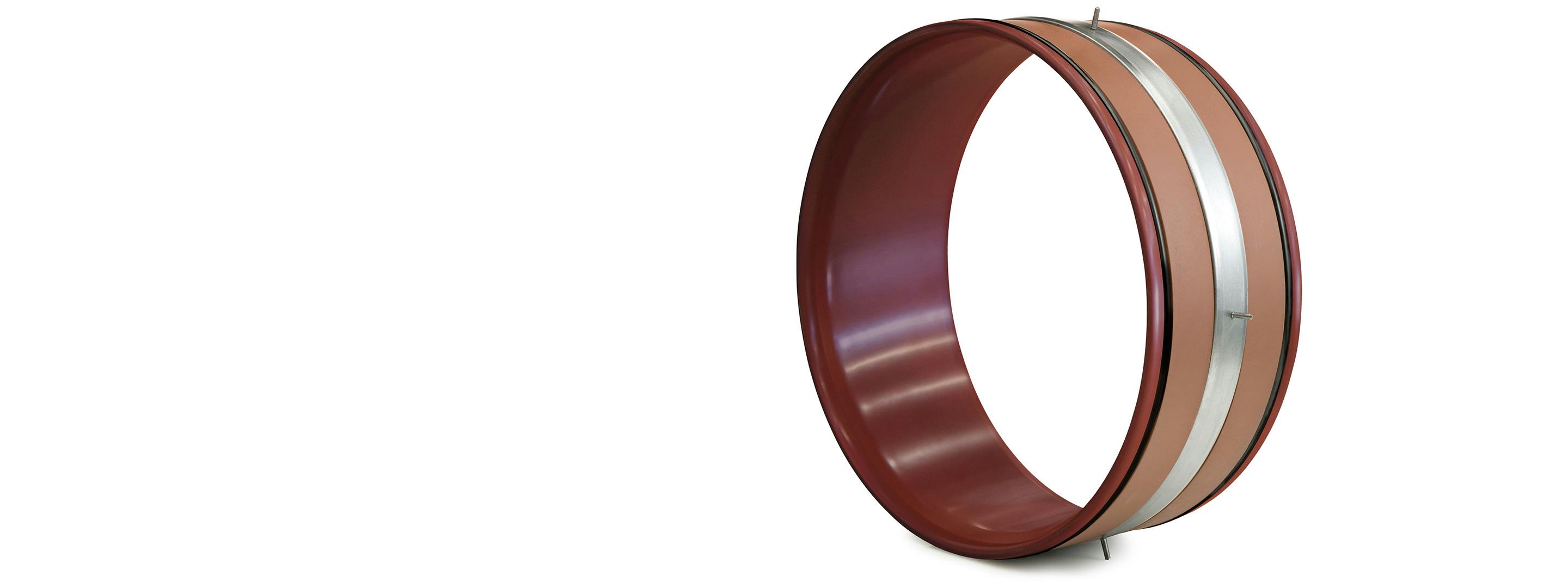

Our Thru-Kote™ connection system uses a patented insert sleeve designed to protect the internal coating during the welding process.

During the welding process, heat generated within the pipe will burn back the internal plastic coating approximately 1 to 2 in. from the welding seam. Thru-Kote sleeves isolate the burn-back of the coating and protects the steel substrate.

Benefits

- Isolates burn-back of internal coating behind the sleeve

- Backing ring and heat tape reduce excessive temperatures

- Holiday-free connection area

- X-ray compatible with API and ASME

- Compatible with Tube-Kote™ coatings

- Suitable for onshore and offshore applications

- Accommodates all configurations of piping systems

- Fast and flexible method of field construction

Configurations

- The Thru-Kote U.B™ sleeve is an unbelled connection system for 2- to 42-in. line pipe designed to protect internal coatings during welding.

- Thru-Kote is a belled connection system allowing for a non-restricted inside diameter (ID).

Related Products

Line Pipe Inspection Services

Improve safety, reduce environmental impact, and maximize pipeline design life with Tuboscope line pipe inspection services.

Internal TK Coatings

Unmatched tubular protection and performance in the most challenging environments.

Zap-Lok Pipeline Connection System

The Zap-Lok mechanical pipeline connection system is a safe, fast, and cost-effective method for pipeline construction.

Custom Coating Services

Our custom-coated accessories help protect your drilling, production, and pipeline applications.

Tubo-Wrap External Wraps

Field-proven, impermeable external coating that provides superior corrosion resistance