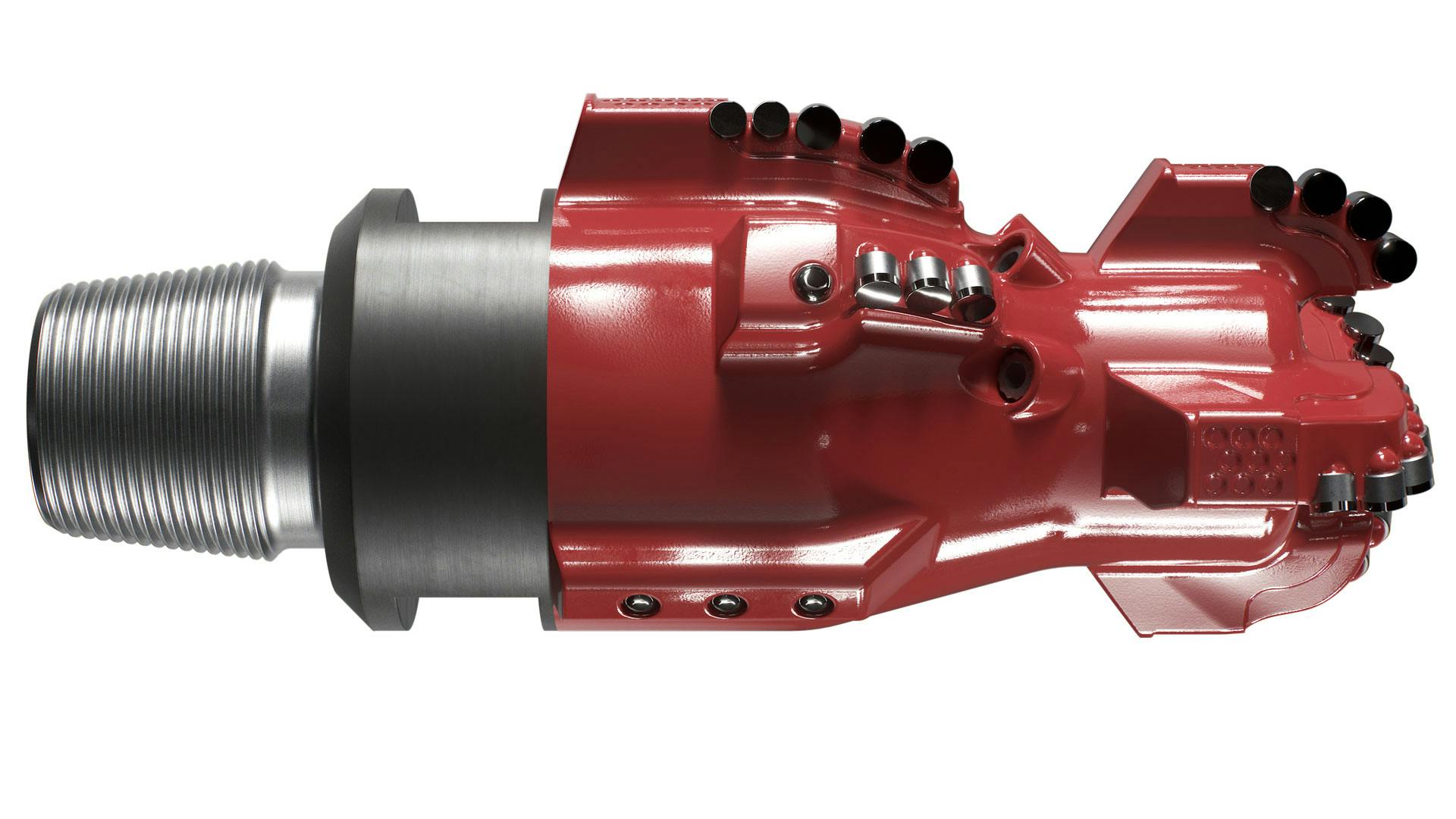

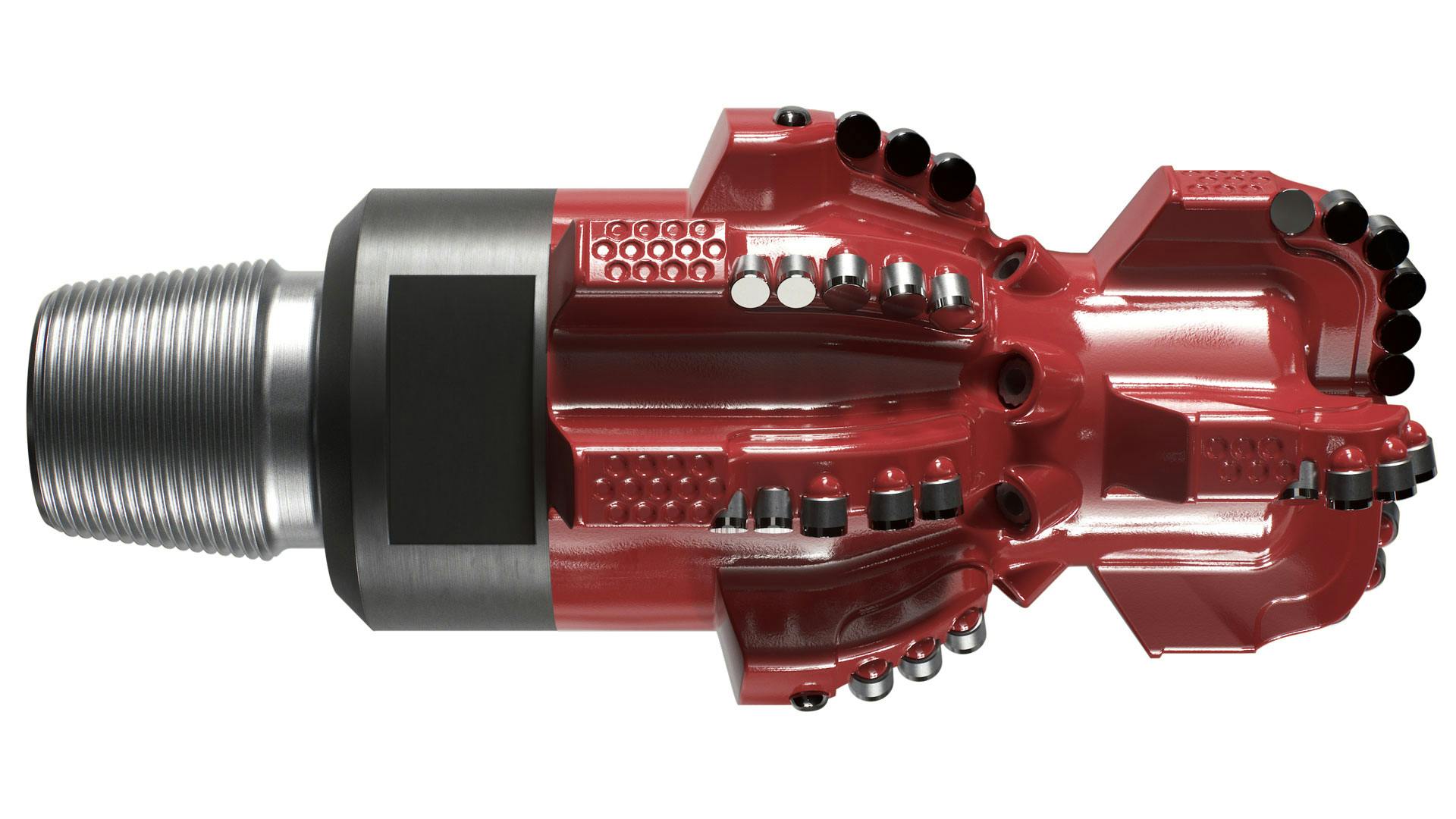

Tektonic Xcentric Bi-Center Drill Bit

Innovative design in bi-center drill bits

In this seventh-generation range of Bi-Center drill bits, close attention has been paid to hydraulics optimization to improve both cuttings removal and ensure effective cutter cooling. In addition to the improved hydraulics configuration, we also look closely at the cutting structure to ensure it is both effective and balanced—not only on a conventional assembly but also when used in conjunction with bent-housing motors. This new design philosophy, coupled with ReedHycalog’s wide range of PDC cutter grades and geometries, results in a state-of-the art bi-center bit with outstanding drilling performance.

Features/Benefits

- Force-balanced cutting structure – This significantly reduces the potential for bit-induced downhole dynamics events, even in demanding applications.

- CFD enhanced hydraulics layout – Optimized nozzle placement and orientation ensures efficient cutter cleaning and cooling and eliminates recirculation of cuttings, reducing balling risk.

- Large selection of premium PDC cutters – Cutter type and geometry can be optimized to suit the demands of each specific application.

- Drillout capable – All Tektonic™ Xcentric Bi-Center bits are designed for effective casing shoe drillout.

- Directionally responsive – All Tektonic Xcentric Bi-Center bit designs are engineered to be directionally friendly and can successfully be used with directional motors with bends of up to 2.2°.

Related Products

Tektonic Drill Bits

Achieve maximum drilling efficiency with the latest generation of polycrystalline diamond cutter (PDC) drill bit technology.