Like all TCS products, TCS-Titanium exhibits unlimited field reapplication capabilities over other TCS products and select competitive products without removal of existing hardbanding.

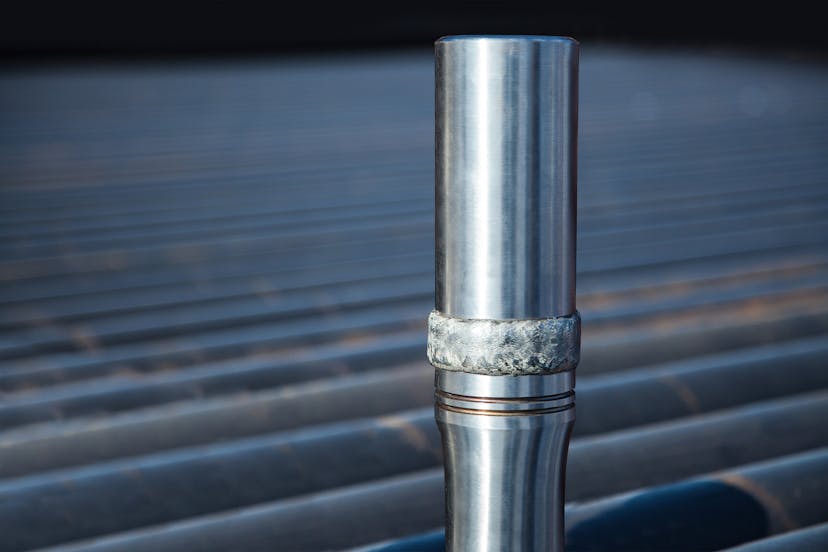

Tuboscope TCS-Titanium is a martensitic chrome-titanium carbide alloy with molybdenum. This popular hardbanding choice features high-stress abrasion resistance and the ability to resist cracking and spalling.

TCS-Titanium is manufactured as a self-shielding, flux-cored, 2.4-mm open-arc welding wire.

TCS-Titanium Features/Benefits

- Dense and uniform grain structure

- Tolerant to variations in pre- and post-temperatures

- >56 Rc (undiluted weld metal hardness)

- Controlled single-pass application

- Removal of previously applied TCS titanium not required

- Can be repaired in remote locations

- Minimal flux residues

- Total overlay integrity with tool joint

- Extremely low coefficient of friction

- High stress abrasion resistance

- Impact, cracking, and spalling resistant

- No shielding gas required

- Casing-friendly hardbanding