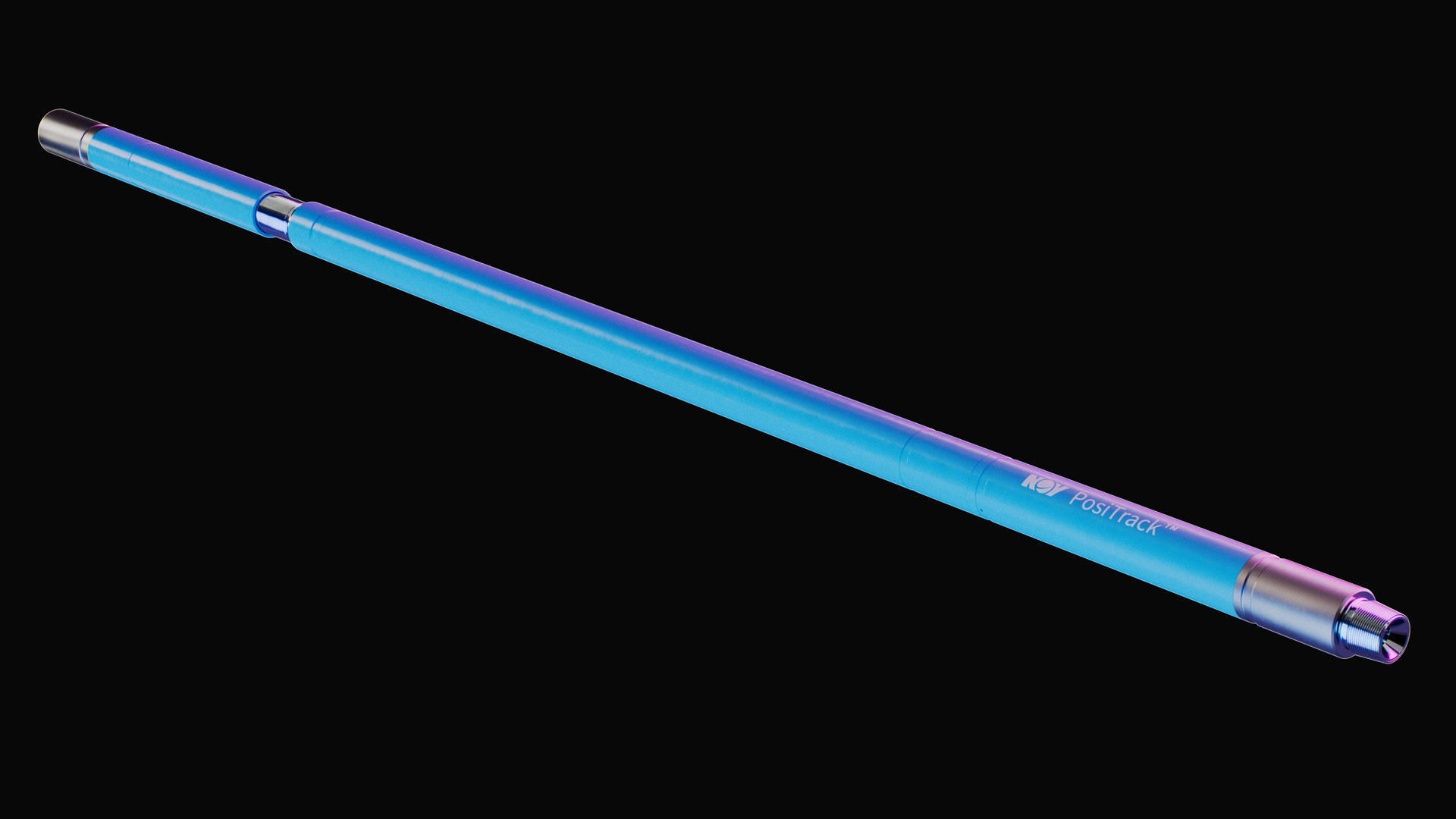

PosiTrack Torsional Vibration Mitigation (TVM) Tool

The PosiTrack™ TVM tool is the new torsional vibration mitigation technology from NOV specifically designed to mitigate torsional instability.

Target torsional vibrations and drilling dysfunctions with PosiTrack.

The PosiTrack™ Torsional Vibration Mitigation (TVM) tool is the new torsional vibration mitigation technology from NOV specifically designed to manage unwanted torsional vibrations above and below the tool while effectively managing weight on bit.

Using a patented pressure compensated telescoping mechanism, the PosiTrack technology absorbs torsional oscillations and vibrations induced by stick-slip, HFTO, drill bit overengagement, and inconsistent weight transfer.

The PosiTrack technology provides torsional stability enabling RSS systems to stay on track improving drilling efficiency. The PosiTrack protects valuable BHA components, reduces drill bit instability, and aids in drilling parameter optimization.

Proven Performance. Unmatched Benefits.

PosiTrack’s international launch was poised for a good start. Brought in to extend the BHA component life in low and high-frequency torsional oscillation (HFTO)-laden application in Mexico, it was run on top of a major RSS / MWD make in an 8 ½” section. Surrounded by BlackBox High Frequency measuring tools, it has made an immediate impact. While building and holding from 4° to 45° in highly interbedded formations, the NOV’s PosiTrack has seen limestones and dolomites with confined stresses up to 25 ksi. In the end, the PosiTrack has made the mark by not letting damaging tangential vibrations propagate to the lower BHA. Radial vibration, too, was effectively mitigated (by over 2.5 g).

Elsewhere, in Alberta (Canada), NOV’s PosiTrack was put to the test in a series of 8 ¾” vertical intermediate sections. These are drilled on conventional motor BHAs with 100% rotation from the surface. This application was particularly interesting as the industry comes to grips with HFTO presence on the motor BHA. The NOV’s PosiTrack did not disappoint and delivered an impressive $250 thousand in savings to a major operator in the area. By enabling the operator to maintain higher and more consistent weight at the bit, each run (of 17 runs in total) has ended at a planned total depth with zero tool failures and competitive dull grades. All the while, the PosiTrack reined vibration levels within safe limits.

Original designs. Best performance. Imitated but never replicated.

Benefits

- Reduces stick-slip by mitigating torsional vibration

- Helps manage HFTO

- Optimizes drill bit depth of cut

- Absorbs torque spikes cause by sudden reduction in drill bit rpm

- Variable/adjustable settings

- Protects RSS tools from damaging torsional vibrations

Related Products

AgitatorHE On-Demand System

Our AgitatorHE system can be activated downhole and on demand based on application needs and customer preference.

AgitatorZP System

AgitatorZP System is NOV's new zero pressure friction reduction tool. With this system, operators can drill farther faster and maintain maximum flow rates even in the deepest laterals.