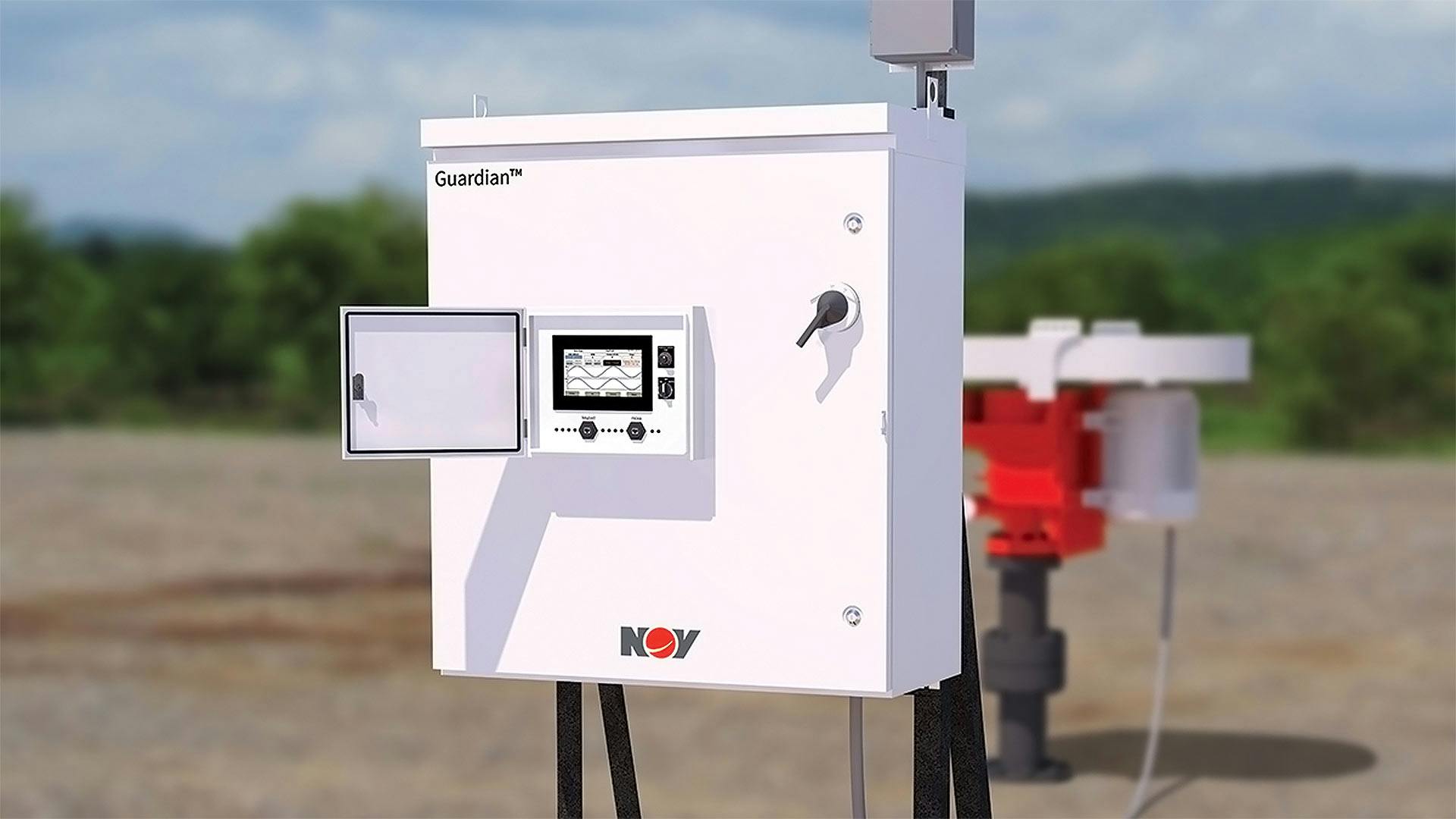

Guardian VFD Pump Controller

Reduce maintenance and running costs while achieving optimum pump performance with our Guardian VFD Pump Controller.

The innovative design of our Guardian™ PC Pump Controller and Rod Pump Controller increases productivity and extends the life of new installations while also providing upgrades to existing installations. By deploying our Guardian PC Pump Controller, operators greatly reduce maintenance and running costs while providing optimum pump performance. Our Guardian PC Pump Controller and Rod Pump Controller come automatically integrated with each Guardian VFD, and no additional external hardware or interfaces are required except for an inexpensive arm position. Our VFD connects to a standard A/C motor and provides maximum well production and lower operational cost.

Guardian VFD

- Guardian PC Pump Controller ensures operational efficiency and control of PC pump artificial lift systems

- Guardian Rod Pump Controller protects rod string during high-torque conditions

- Easy-to-use operator interfaces

- Effortless integration into existing SCADA networks

- Minimizes downtime using our integrated control methods and proprietary software suite

- Simultaneously monitors pump performance and control pump-off

Control methods (GII Plus model)

- Automatically changes speed of the pump to optimize well performance through remove-control methods

- Set-up primary and secondary control methods to operate simultaneously

- Downhole pressure sensors

- Fluid over pump

- High-torque control

- Production flow

- Flowline and casing pressure

- Tank level

Guardian OnSite software

- Retains central depository of information

- Acquires real-time performance data

- Maintains two-way communication between operator and pump

Standard configurations

- Main-line circuit breaker

- Lightning arrester

- 5%-line reactor

- Control transformer

- Accessible terminal connections

- Low maintenance

Security

- Restricts access based on user roles

- Detailed change log tracks configuration changes and updates

Safety and performance

- Simple and easy-to-use operator interfaces

- Automatic, non-moving A/C motor tuning

- cULu Listed enclosure

- Local plotting of performance information

- Safe access to data and diagnostic interface ports

Services

- Highest level of support and training at preferred locations

Features

- Versatile application and outstanding performance in the hardest conditions

- Simple installation and start-up

- User-friendly interface

- Flowline and casing pressure inputs

- Maximizes energy efficiency

- Counterbalances weight adjustment reporting

- Real-time position and torque display

- Support for extreme climate conditions

- Multispeed options for customizing up- and downstroke speeds

- Automatic pump fill detection on each stroke

- Belt slippage prevention and detection

- Detailed fault history with real date timestamp

- Energy meter reports kWh consumption

- On/off timer control

Benefits

- Remote pump monitoring and control capabilities

- Interactive communication between the operator and the well

- Real-time well diagnostic and control functionality

Accessories

- Harmonic filters

- Surface-pressure sensors (flowline/casing)

- Downhole-pressure sensors and position sensors

- Load cells and braking resistors

- Communications (satellite/cellular/radio)

- Running/fault lights

- Power line-in/motor/Presco connectors

- Motors: Totally enclosed fan-cooled (TEFC) or TEXP