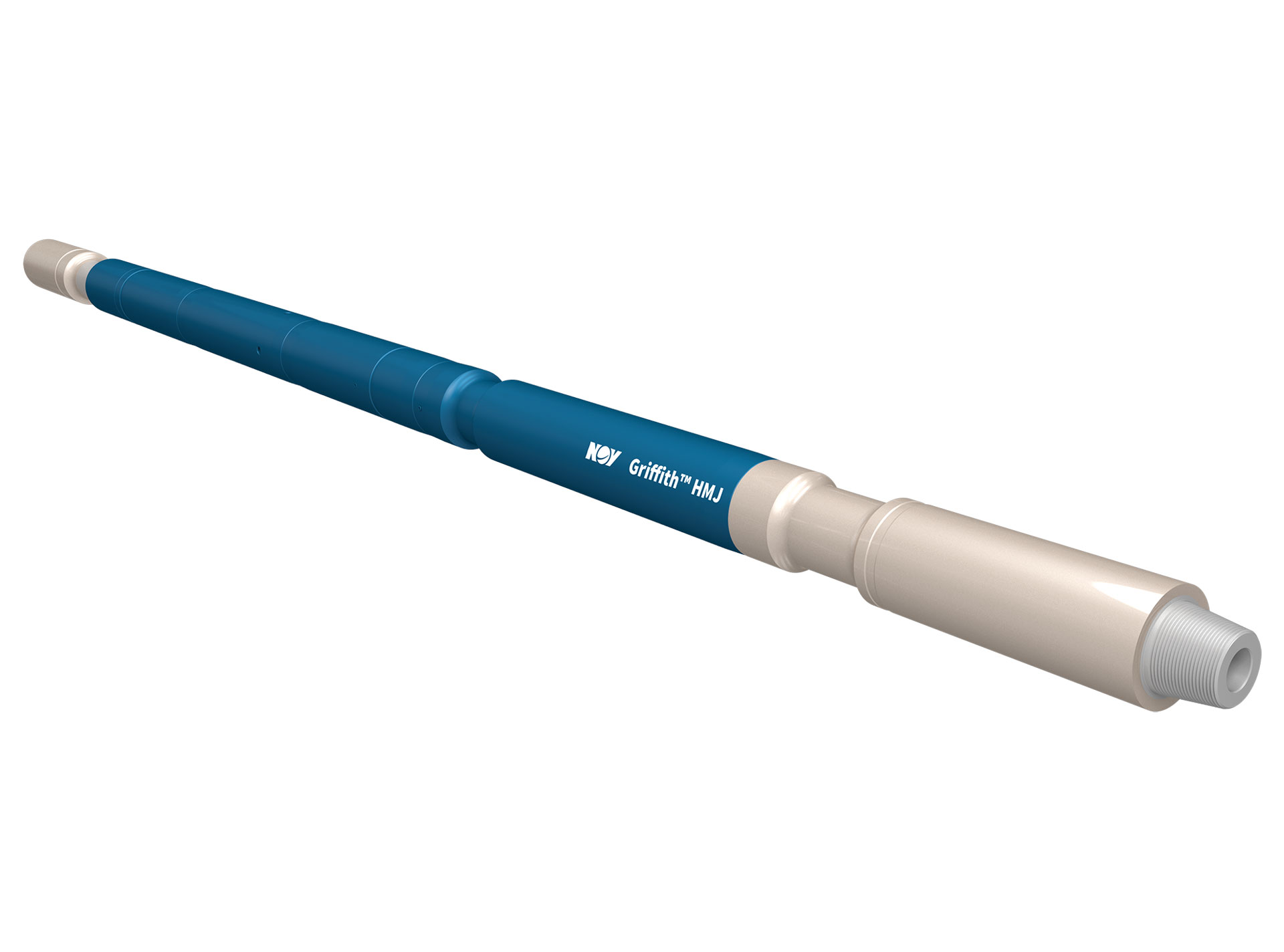

Griffith Hydraulic/Mechanical Jar

Our Griffith hydraulic/mechanical drilling jar is well-suited for virtually every drilling condition.

Specifically designed to overcome the limitations of purely hydraulic or mechanical drilling jars, the Griffith™ HMJ provides the advantages of both tools in one solution.

Offering a hydraulic delay in the upstroke and acting as a traditional mechanical jar in the downstroke, the HMJ provides consistent firing regardless of the direction or temperature downhole. Internal mechanical latches allow the jar to be run in tension, neutral, or compression in the drill string. Additionally, these latches hold the jar in place during drilling and tripping operations, eliminating the need for an external safety collar and removing a falling hazard from the rig floor.

Performance

To jar down, the drill string is lowered until the compressive force applied to the jar exceeds the preset mechanical latch setting. The latch releases, allowing the mandrel to accelerate to the fully closed position and creating a downward jarring impact. Raising the drill string until free movement stops indicates the latch has reset. The jar is ready for another jarring cycle or to resume normal drilling operations.

Griffith drilling jar mechanical latch

All Griffith drilling jars (with the exception of the slimhole 3½-in. OD and smaller) feature our mechanical safety latch mechanism. The mechanical latch firmly holds the mandrel in the neutral position in relation to the jar body, presenting any unaccepted jarring while making connections, tripping in or out of hole, or when tagging bottom. The latch is preset to release when either a tinsile or compressive force is applied to the jar and exceeds the forces seen during normal drilling operations. The latch release settings can be adjusted at the service facility to expand the range of the jar placement possibilities within the drill string. The latch mechanism allows the jar to run in the drilling string in tension or compression or at the neutral point within the range of the preset release settings.

Features/Benefits

- Dependable design – Hydraulic upstroke with a mechanical downstroke

- Continuous, consistent performance – Modified fluid shearing technology from the aerospace industry provides reliable firing.

- Improved safety on the rig floor – The internal mechanical latch prevents unexpected jarring when making connections or drilling and eliminates the need for an external safety collar.

- Versatility – Jar placement can be in tension, neutral, or compression.

Related Products

Griffith Double-Acting Hydraulic/Mechanical Drilling Jar

GriffithForce Double-Acting Hydraulic Drilling Jar

The GriffithForce double-acting hydraulic drilling jar offers dependable performance when jarring for extended periods.

ShockForce Drilling Jar

Achieve industry-leading impact forces and extended stroke length at downhole pressures up to 30,000 psi with our hydraulic drilling jar.

PowerStroke Drilling Jar

The PowerStroke drilling jar was engineered with Bowen technology to provide control, power, and flexibility for extended drilling periods in the most demanding applications.

Related Tools