As part of the project, NOV received an order for a 710-kW fermenter for use at ENOUGH’s mycoprotein biorefinery located in San van Gent, Netherlands. The fermenter will be used to help produce a high-volume of plant-based foods, lowering the environmental impact of the agriculture industry.

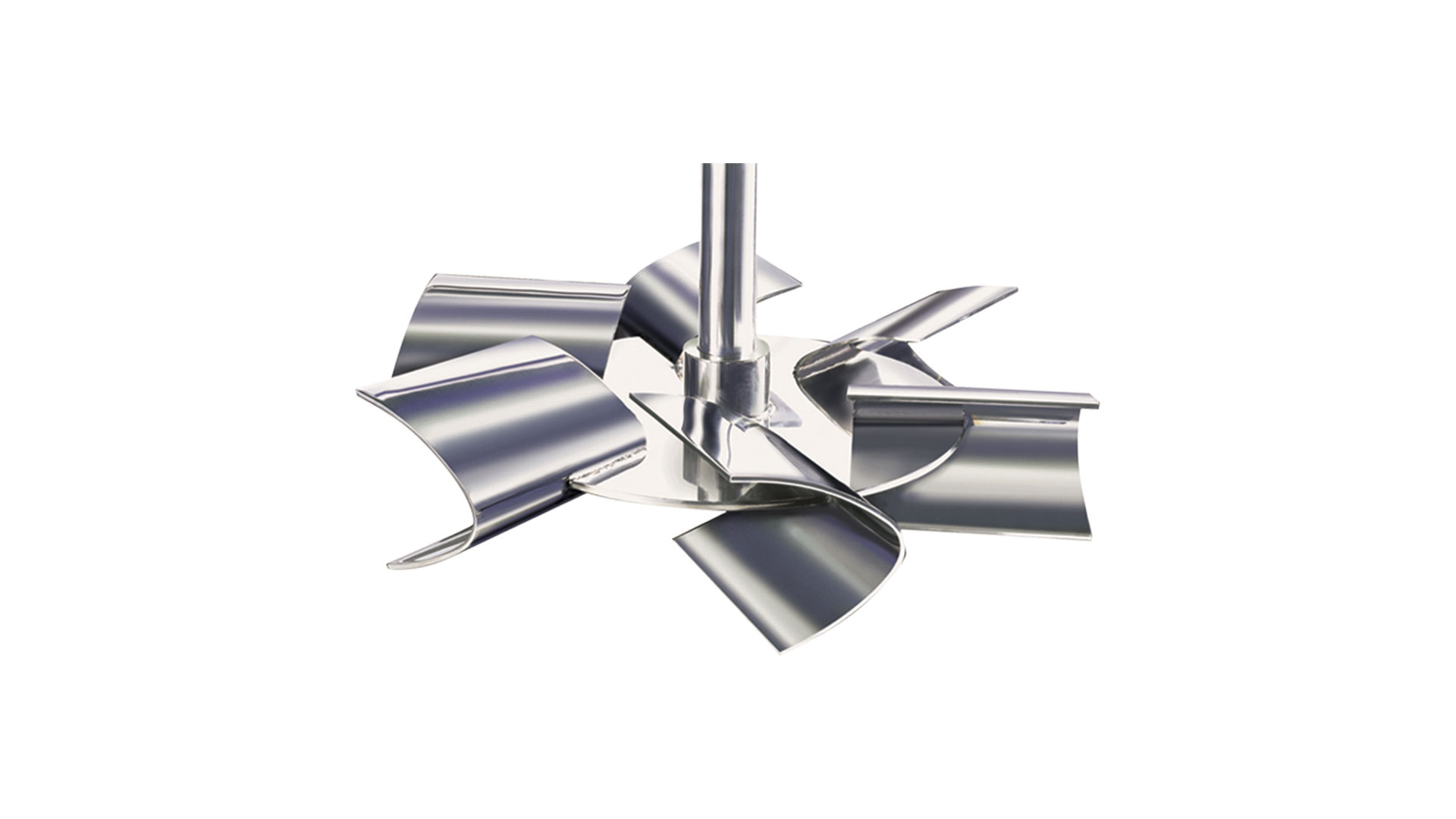

Key to these operations is the patented, parabolic blade geometry of NOV’s BT-6 impeller, a third-generation gas dispersion technology, 50 years in the making, providing capability nearly six times that of the industry-standard. Impeller technology breaks gas into fine bubbles, holding it in liquid long enough for the fermentation process to take place. Small bubbles mean the contact area between the liquid and the gas is high, whereas larger bubbles will lead to inefficient operations.

The reactor used in this project is 10-tons, and the BT6 impeller is used alongside our MW-4 High efficiency impellers; all parts specially designed to fit together in accordance with EHEDGE Standards. Its high-value, highly polished design meets the customers’ gassed power requirements. When operations increase to meet expected demand, it can annually produce 50,000-t, based on 10 week fermentation cycles. A second reactor is coming online next year, with a total of six units in the Netherlands likely soon, to be followed by others around the world.

The complete agitation system is designed to prevent dirt from being trapped within the vessel; from special mechanical seal designs to steady bearings used to ensure nothing can grow and contaminate batches. The hygienic design drains fluids, making it a globally superior product of choice.

For this unique project, NOV worked with the customer throughout the entire process, offering overall support and supplying what was needed.

This included working on a detailed design, helping them scale up from the lab to full-scale with the use of expert design software. The software allows NOV to model customers’ challenges by entering their tank details and calculating ways to optimize their processes. Computational fluid dynamics (CFD) was also done in-house at NOV, complementary to design software, with models predicting flow pattern within the system.

NOV will also be onsite supporting the customer. Service engineers will assist with installation, ensuring all parts are aligned correctly.

The best-on-market quality of the BT-6, used alongside our MW-4 impellers, offers a safer, more stable design, with less vibration and components that can be easily and carefully lifted and moved into place.