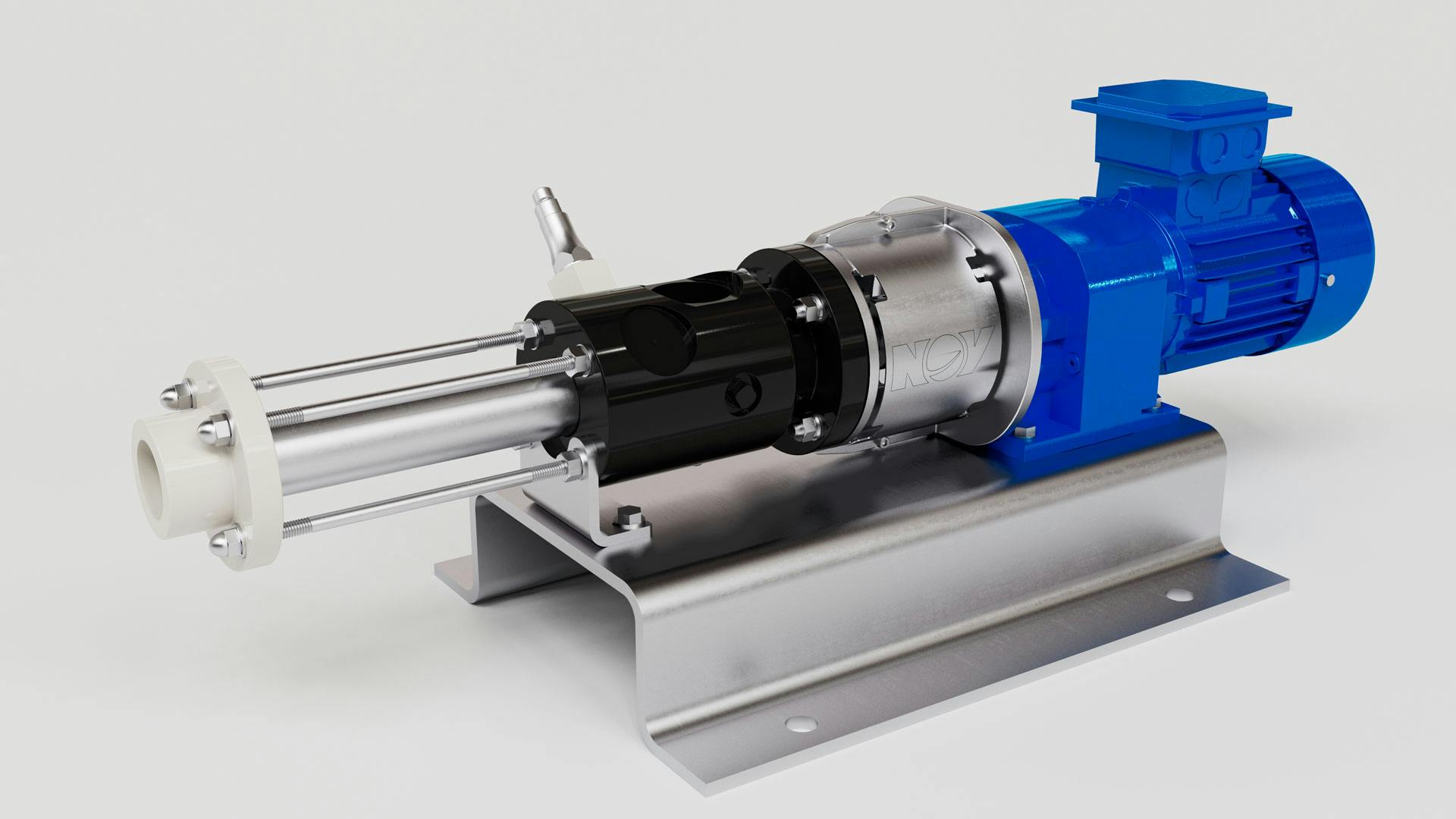

Designed for use where accurate, low flow dosing or transfer pumps are required for either intermittent or continuous dosing, the pump has high tolerance to aggressive chemicals (0-14PH) and is backed by the renowned reliability of NOV products.

NOV has been at the forefront of progressing cavity pump design since 1936. Our experience supports the vast array of needs facing our global customer base. It also enables us to develop high quality solutions which lead to efficiency improvements across dozens of industries. Our pumps have a repeatability of ± 1%, and the gentle pumping action is ideal for delicate, shear-sensitive products.

The Low Flow Metering Range Pump includes enhanced element offerings with improved precision metering control technology, reduced break-out torque, and excellent slow-speed performance. These elements help to expand the scope of metering applications, while still supplying each fluid with a smooth, pulsation-free flow.

Advantages of the Low Flow Metering Range Pump include:

- Handles abrasives, corrosives, solids in suspension, and viscous fluids

- Works with pressures to 300 psi or 24 bar

- Self-priming, high suction lift capability

- Low shear pumping action

- Low power consumption and operating costs

- No valves to clog, stick, or vapor lock

- Pressure capability is independent of speed

- Compatible with Integral VFD/motor controls

The use of different stator materials enables the pump to be used for a wide range of applications and products, including everything from acids and alkalis, to wastewater chemical injection, to chemical processing for various industries, to the pharmaceutical industry.

Constructed of the most dependable materials, most of the pump components are supplied in stainless steel. The suction chamber is manufactured in high-density polyethylene. The end cover and mechanical seal housing is made of polyvinylidene fluoride. For severe chemical environments, internal pump components are supplied by Hastelloy.

Fully sealed joints maximize life and minimize downtime, while packing, single, and double mechanical seals are available in a variety of materials to support the most corrosive applications.

Gearbox and motor options include close coupled, long coupled, synchronous speed motor, fixed speed gearbox, and frequency inverter.

The latest motor control enhancements, plus decades of metering pump experience, equal a winning combination, giving customers the precision metering they demand.

NOV offers a wide range of integral VFD/motor controls for improved metering accuracy and repeatability.

In addition, a flow meter is available as an option for flow or temperature monitoring, up to 72 bar. The Smart Metering pump is supplied with an integrated PLC and inverter, allowing sensors to provide feedback on the operating conditions. Set points can then be programmed for the specific application, allowing the pump to correct any deviations from the required task.

This simplifies automation system integration and reduces installation costs. Sensor data can be fed into our system, allowing for remote monitoring and predictive maintenance.