Nitrogen Pumping Components

The world's most advanced nitrogen pumps and vaporizer systems for coiled tubing, fracturing, and industrial applications.

While most manufacturers purchase the critical components for this highly specialized equipment, we meet the demands of oilfield, industrial, and pipeline services by designing and manufacturing our cryogenic cold ends, warm ends, boost pumps, and vaporizers to ensure that you receive a fully engineered system with single-point accountability.

Liquid Nitrogen Pump Power Ends

Our Hydra Rig high-pressure pumps are specifically designed to deliver high flow rates at high pressure while providing exceptional low flow rate turndown. These pumps utilize low-friction roller bearings and a pressure feed lube system for positive lubrication, ensuring increased pump life over conventional pumps.

Our design uses low-friction roller bearings to enhance durability—particularly at low speeds at which other pumps using journal bearings are most vulnerable. This design also operates at a much cooler temperature, which means less lube oil system requirements, saving weight without sacrificing unit durability.

Our pumps are internally balanced so that an externally mounted counterbalance does not compromise the reliability of the pumps. This enhancement also provides a much smoother pump operation.

NP-200 Liquid Nitrogen Triplex Pump

The NP-200 triplex nitrogen pump is designed for durability and pumping rates of up to 275,000 scfh (7,780 scmh). A maximum rod load of 21,500 lb (9,752 kg) enables 15,000 psi (103 MPA) working pressure at rates up to 107,500 scfh (3,040 scmh).

The welded steel case design provides strength where needed while reducing the overall weight. The design is coMPact for a minimal footprint when installed. Typical hydraulic drive packaging enhances flexible installation of the nitrogen pump without drive shafts to align.

NP-1000 Liquid Nitrogen Triplex Pump

The NP-1000 triplex high-pressure pump was specifically designed to deliver high flow rates at high pressure with rates up to 1,097,000 scfh (31,000 scmh). The maximum rod load is increased to 73,500 lb (33,339 kg) (coMPared to 58,000 lb for competitive offerings), enabling 27% increased working pressure without changing to smaller cold ends.

This pump is capable of rates up to 649,000 scfh (18,400 scmh) at 15,000-psi (103-MPa) working pressure.

NP-1600 Liquid Nitrogen Quintuplex Pump

The NP-1600 high-pressure pump satisfies the market requirement for high-pressure pumping rates up to 1,828,000 scfh (51,700 scmh). This pump delivers the highest flow rates at high pressure we offer while providing exceptional low flow rate turndown.

The NP-1600 utilizes all the advancements of the NP-1000, and this quintuplex design achieves even higher flow rates.

The maximum rod load is increased to 73,500 lb (33,339 kg) (coMPared to 58,000 lb for competitive offerings), enabling 27% increased working pressure without changing to smaller cold ends.

This pump is capable of rates up to 1,082,000 scfh (30,600 scmh) at 15,000-psi (103-MPa) working pressure.

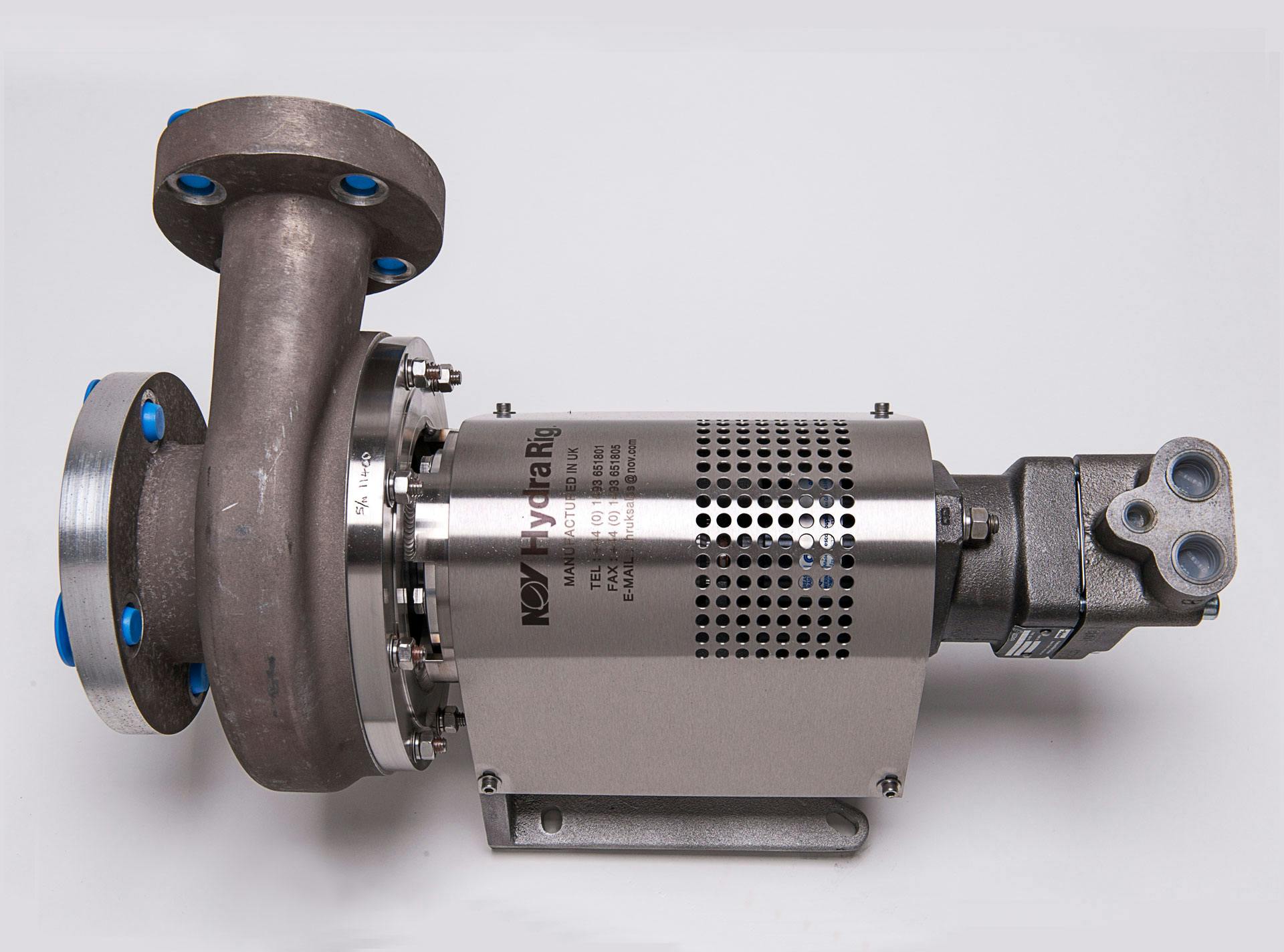

Liquid Nitrogen Boost Pumps

Cryogenic boost pumps are specifically designed to pump liquid nitrogen to boost inlet pressure to supply cryogenic cold ends, prevent cavitation, and extend the life of the nitrogen pumping unit.

The Hydra Rig™ 1.5 × 2.5 × 6 in. and 2 × 3 × 6 in. boost pumps are sized perfectly to meet the supply requirement through the entire range of cold ends, from the low-flow 1.25-in. diameter to the high-demand 3.25-in. diameter.

Our boost pumps encompass the reliability of field-proven components together with unique concepts such as the double-lip seal and replaceable sleeve. These features ensure the operator has a reliable and user-friendly pump that is easy to maintain in the field without the need for special tools, minimizing downtime and reducing repair costs.

Liquid Nitrogen Cold Ends

Our Hydra Rig cryogenic cold ends are available from 1¼ to 3¼ in. and working pressures up to 15,000 psi. Our range of cryogenic cold ends is specifically designed for use with the Hydra Rig nitrogen pump power ends but are coMPatible with most other manufacturers' power ends.

Nitrogen Steam Vaporizer

Our Hydra Rig nitrogen steam vaporizer unit offers an alternate solution for pipeline and industrial process work applications. With maximum flow rates of 494,285 scfh (14,000 scmh) and pressures up to 500 psi (34 bar), our nitrogen steam vaporizers provide a cost-effective solution to nitrogen projects with low pressure and high flow-rate conditions.

This equipment is simple in design and made for easy operation, with integrated control systems allowing the operators to control and set discharge pressure and temperature parameters specific to their operation.

The nitrogen steam vaporizer unit is available complete with an integrated boost pump package. Where high-temperature steam is available on-site, this vaporizer is the perfect solution to reducing project headcount and allowing efficient nitrogen operations. Additionally, the vaporizer can be used in conjunction with an ambient vaporizer or plant gas to super-heat the product gas to 392°F (200°C).

Nitrogen Vaporizers

Direct-Fired Vaporizers

The Hydra Rig™ proprietary diesel-fired burner assembly has stainless steel construction, a propane-assisted ignition system, integrated fuel/fan controls for simplified unit operation, a single combustion chamber, and a single flame detector.

Our direct-fired vaporizers use ambient heat, fan speed sensors, and a quench air system for a more uniform temperature and improved efficiency. This also protects the heat exchanger from overheating.

Available in multiple sizes for different maximum flow rates. All Hydra Rig direct-fired vaporizers are rated to 15,000 psi (103 MPa).

Non-Fired Vaporizers

Our vaporizer pots utilize the heat generated by an engine and other heat sources to transfer heat from the cooling system to the liquid nitrogen. These are highly efficient, highly reliable, and have a small footprint. Rated for 10,000 psi (68.9 Mpa), a single vaporizer pot is capable of 180,000 scfh (5070 scmh) at 70°F (20°C). The maximum rate is dependant on sufficient energy transferred to the coolant system.

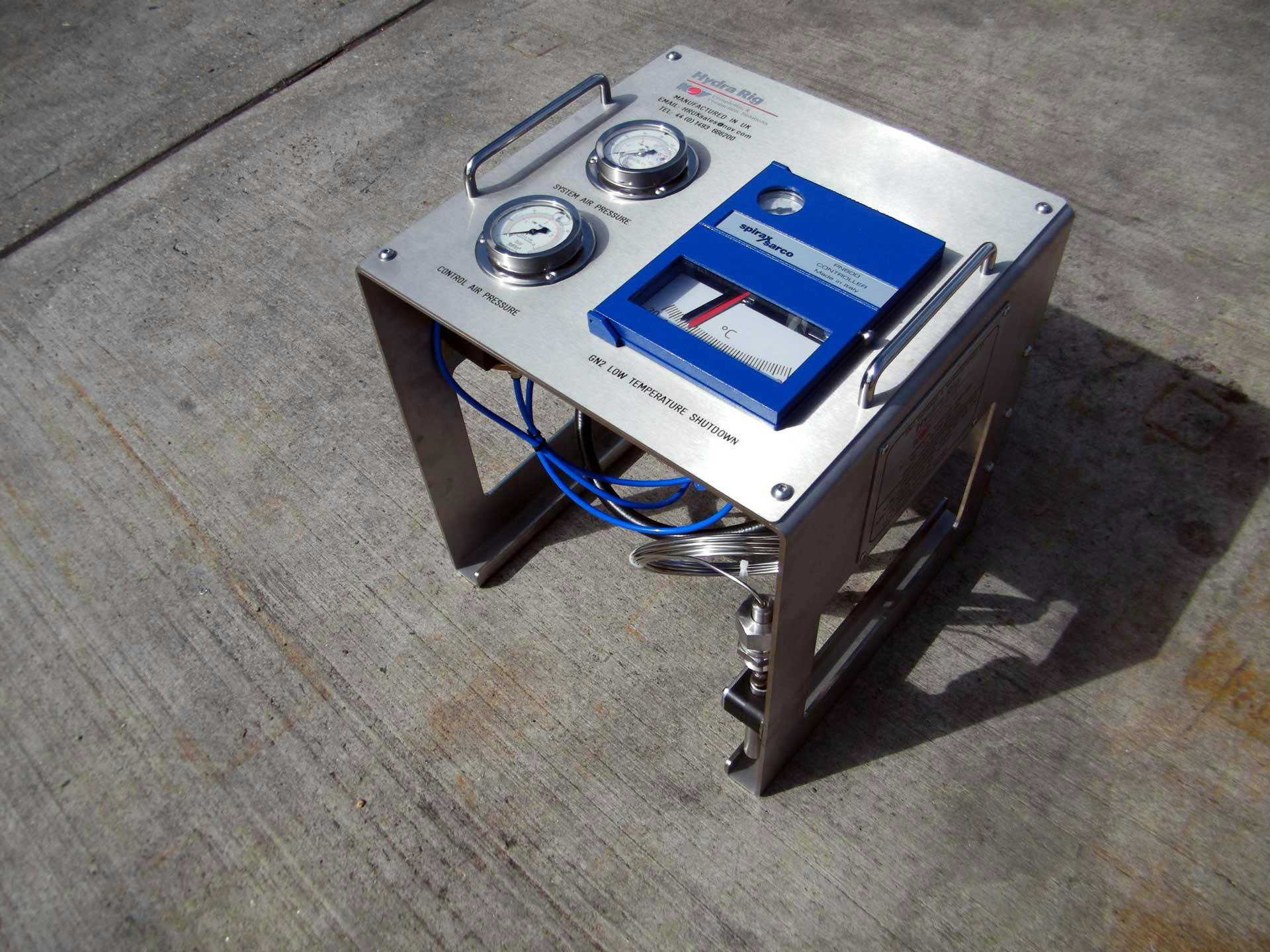

Temperature Shutdown Skid

Our simple-to-use Hydra Rig temperature shutdown skid is a compact and portable assembly for field use. The skid adds extra safety features essential to all nitrogen pumping operations with coiled tubing, pipeline testing and pigging, purging and leak detection, and most land-based and offshore operations requiring nitrogen.

This stand-alone skid monitors the temperature downstream of the nitrogen unit discharge valve. If the discharge temperature falls below or rises above the setpoint, a valve opens to shut down the triplex pressure pump of the nitrogen unit. Pumping can either automatically restart when the discharge line warms up or cools down or manually reset by the operator.

Cryogenic Service Exchange Program

We design and manufacture cryogenic cold ends and boost pumps in-house and offer worldwide service and support from strategically positioned service centers. This program helps our global customers with the routine servicing of their cold ends and boost pumps.

We currently have offices in the UK (servicing Europe), Dubai (servicing the Middle East), Malaysia (servicing the Far East), Calgary (servicing Canada), and Ft. Worth (servicing the USA).

This program is not just limited to Hydra Rig cold ends; we can support other supplier models and provide new cold ends to replace other manufacturers' models withHydra Rig cold ends.

Product Updates and Bulletins

Sign up to automatically receive the latest product updates and bulletins available so you stay up to date on your coiled tubing and nitrogen equipment. For instructions on setting up your subscriptions, view the step-by-step directions.

Need assistance? Contact us at [email protected].

Related Products

Intervention and Stimulation Aftermarket Solutions

Reduce total cost of ownership of your coiled tubing, stimulation, acidizing, wireline, sand handling, and cementing equipment with our aftermarket solutions.

Coiled Tubing and Well Service Support Pumps

Our Rolligon, Enerflow, and Wilco lines of coiled tubing and well support pumps were developed to accommodate the demands for today's operations.

Nitrogen Pumping Unit Direct Fired

Our Hydra Rig trailer-mounted nitrogen units can be customized to fit your operational needs—in both non-fired and direct-fired configurations.

Nitrogen Pumping Unit Non-Fired

Our non-fired trailer-mounted pumping units come standard with a diesel engine, gearbox, NP-200 nitrogen pump, nitrogen boost pump, water bath vaporizer, hydraulics, liquid nitrogen storage tank, and necessary piping and controls.

Related Tools