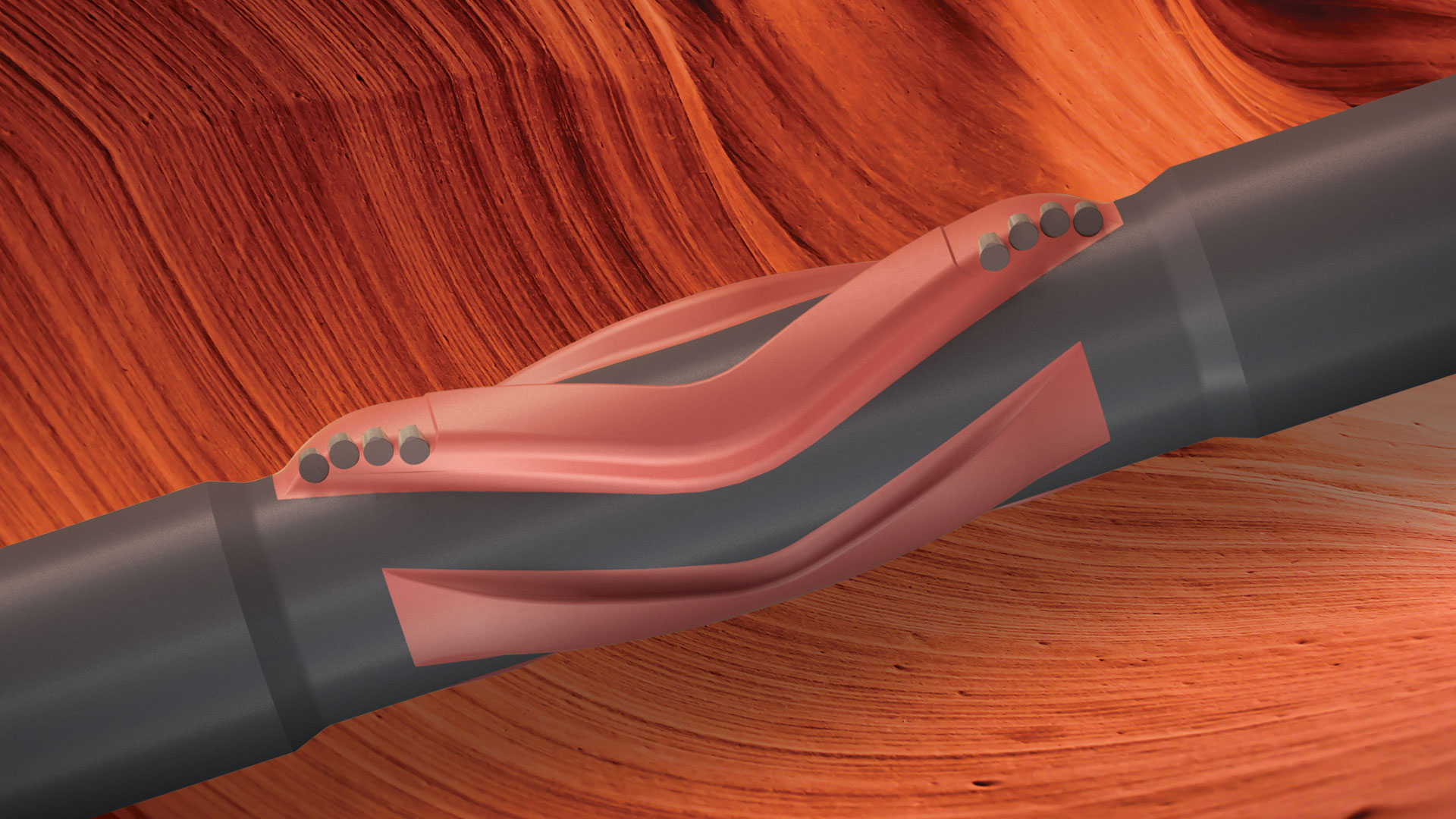

Boomerang Reamer

Streamlined design and reduced torque delivers high-quality wellbores and greater operational efficiency for the Asia-Pacific (APAC) region

Thousands of years ago our ancestors developed a revolutionary new weapon – the boomerang - which significantly improved their hunting efficiency and provided a strong advantage over their rivals. In the same way, ReedHycalog has developed a new, second-generation wellbore conditioning tool for the Asia Pacific (APAC) market which improves both drilling and tripping performance, appropriately named the Boomerang™ reamer.

The Boomerang reamer can result in true cost-per-foot reductions by yielding notable time savings when tripping in and out of hole. In addition, wiper trips can be eliminated or greatly reduced, and casing running speed is also improved, all of which results in significant time savings and cost reduction. The Boomerang reamer enhances drilling efficiency by improving wellbore quality which results in reduced contact between the drillstring and the wellbore. Surface torque is not only decreased, but also improved weight transfer occurs. By leveraging our in-house developed proprietary Multifunctional Advanced Placement Software (MAPS™), optimal placement in the drillstring is ensured, resulting in maximum tool efficiency.

The Boomerang Reamer can be fitted with any of ReedHycalog’s industry-leading grades of polycrystalline diamond compact (PDC) cutters to ensure you have the optimal tool design for your specific application. Only ReedHycalog offers this array of cutter selection to guarantee the most efficient, cost-effective solution enabling you to reach the technical limits of today’s drilling challenges.

One-piece construction

The Boomerang reamer is manufactured from a single piece of steel containing material properties that optimally match the connection tool requirements. The one-piece construction ensures a strong, robust design that is properly paired with the adjacent drillstring components.

Dual-height, dual-function blade design

By utilizing active blades set higher than the passive blades, the tool both conditions and slightly enlarges the wellbore to significantly improve the efficiency of the tool. This enlargement ensures that the bit will be able to pass through the wellbore without the need for backreaming and that casing or completions can be landed quickly and successfully.

Multifunctional Advanced Placement Software (MAPS)

MAPS, which is our exclusive in-house-developed software, enables Boomerang reamer placement in the bottomhole assembly, where it is most beneficial from a borehole conditioning perspective. Accurate placement also ensures there are no negative effects on the bending stresses or contact forces at any point in the interval through which the tool will be run.

Low-torque cutting structure

We designed the Boomerang reamer to generate less than 5% of the reactive torque generated by the bit with which it is used. In most applications, this results in reduced surface torque when compared to similar offset runs that do not include the Boomerang reamer in the string.

Bi-directional cutting structures

Enhanced cutting structures ensure that the tool is actively improving the wellbore when drilling ahead, as well as when the string is rotating and moving in either direction.

Maximized tool internal diameter

This intentional design helps to minimize pressure loss through the tool; it also allows fishing of most retrievable measurement-while-drilling (MWD) components.

Re-engineered blade layout

Our tool’s blade layout offers maximum protection to the cutting structure during drillout and increases the blades’ efficiency when agitating cuttings on the low side of the wellbore in high-angle directional applications. The rounded, continuous blades have been designed to afford greater gauge protection in highly abrasive applications while improving sliding efficiency in high-angle positive displacement motor applications.

Large selection of premium PDC cutters

The cutter type on the Boomerang reamer can be optimized to suit the demands of each specific application.

Related Products

DL Reamer

Cost-effective, real-time solution that delivers improved wellbore geometry and reduced trip times

ION+ Premium Drill Bit PDC Cutter Technology

The next generation of premium PDC cutter technology with enhanced design characteristics that deliver unparalleled drilling efficiency and durability.

Tektonic Drill Bits

Achieve maximum drilling efficiency with the latest generation of polycrystalline diamond cutter (PDC) drill bit technology.