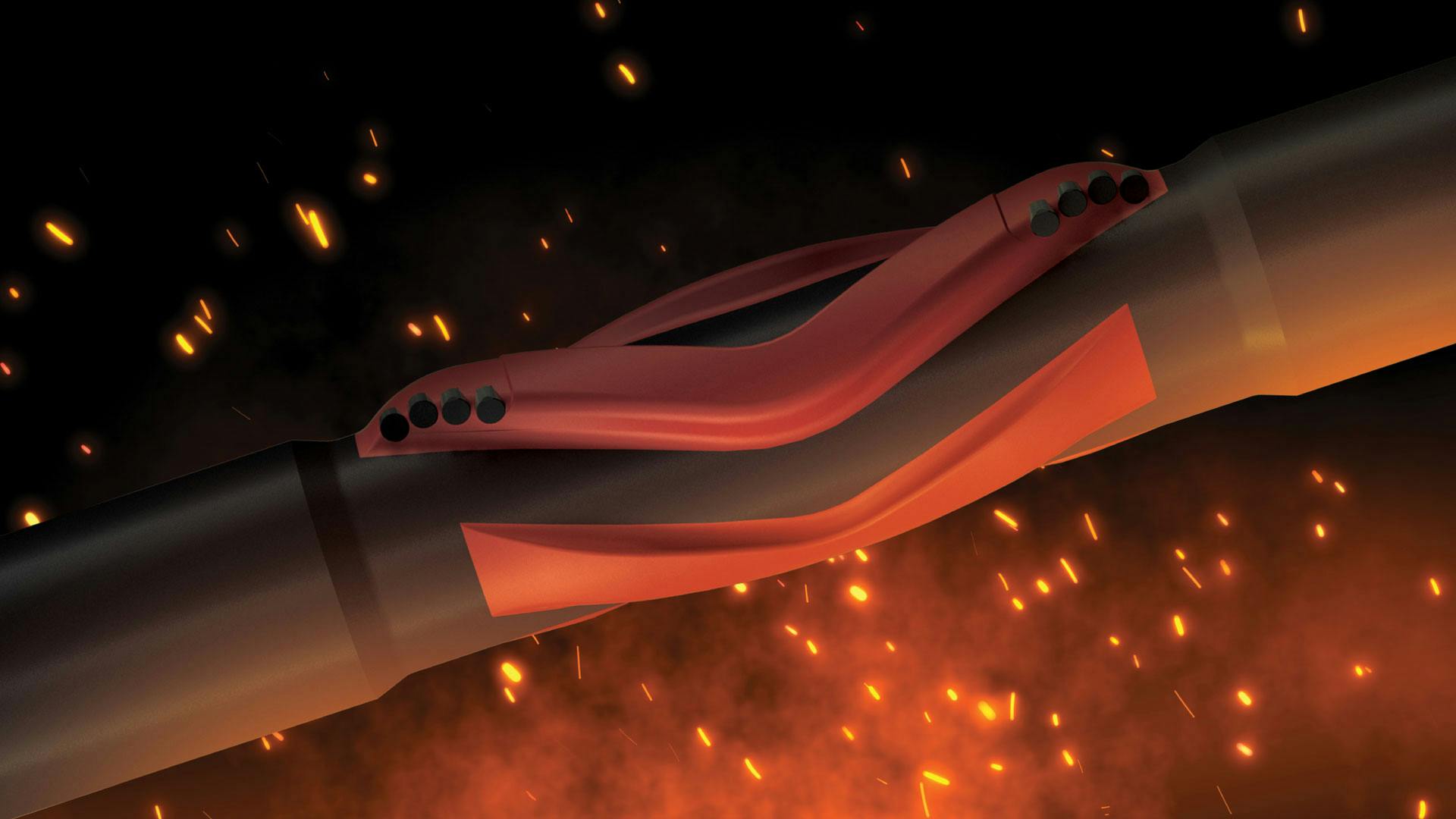

The Fuego Reamer includes new design features, concepts, and materials proven to be highly effective when paired with our Fuego drill bits series. It can improve weight transfer to the bit, reduce string-generated torque while drilling, lower time spent reaming or backreaming during connections and trips, and even eliminate the need for dedicated clean-out runs. All these benefits result in time savings, reducing the overall drilling cost of your well.

Fuego bit designs have significantly improved drilling performance in Latin America, drilling both farther and faster than previously imagined possible, while exhibiting excellent directional response and resulting in entire hole sections being completed in a single bit run.

Due to eliminated trips associated with multiple bit runs, wellbore quality is more important than ever when monitoring drilling performance and efficiency. Reduced trips associated with multiple bit runs can increase the probability of tight spots and ledges and cutting bed accumulations.

The Fuego Reamer has a smaller pass-through size than the drill bit (nominally ⅛” smaller) and is designed to slightly enlarge the wellbore. To work effectively, the correct placement within the bottom hole assembly (BHA) is critical. NOV’s proprietary Multifunctional Advanced Placement Software (MAPS™) is operated by our locally based, experienced Drilling Solution Engineering (DSE) team and ensures the reamer is optimally placed while analyzing bending stresses and contact forces throughout the run for safe operation.

Like our Fuego drill bit series, the Fuego Reamer can be fitted with any of ReedHycalog’s industry-leading grades of polycrystalline diamond compact (PDC) cutters to ensure top performance in the challenging and diverse applications of Latin America. Only ReedHycalog offers this array of cutter selection, guaranteeing the most efficient, cost-effective solution when you run the Fuego Reamer in conjunction with a similarly equipped Fuego drill bit. This dynamic combination enables you to reach the technical limits of today’s drilling challenges.

“The Fuego Reamer can improve drilling efficiency on the BHA by reducing torque created in the wellbore trajectory. Its slight eccentricity helps to minimize the points of contact of the drill string over the wellbore, which translates into better weight transfer to the bit and less energy loss,” said Alejandro Castro Diaz, Technical Sales Engineer.

Learn how the Fuego Reamer can help in the most challenging applications in Latin America here, or contact your local ReedHycalog representative.